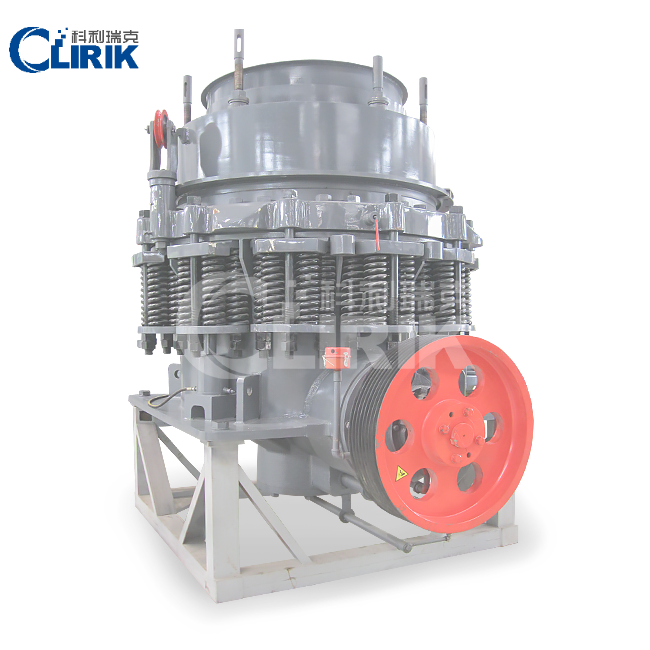

Product Overview

CS Series Cone Crusher is mainly used for the second-stage crushing and third-stage crushing in metal mines and construction sand and gravel processing. Because of its strong crushing capacity and large output, the sand production line using hydraulic cone crusher is more used for river pebbles For the crushing of medium and hard materials. such us iron ore, granite, limestone, quartzite, sandstone, cobblestone and etc、.

Product Advantage

- High yields and high-grade final products

- Overload protective system can effectively ensure the safety of the crusher.

- Easy to control discharging size by using different crushing cavities and adjusting devices.

- With grease seal and upstage sealing element imported from Japan, provide sturdy guarantee for long-playing stable operation of the machine.

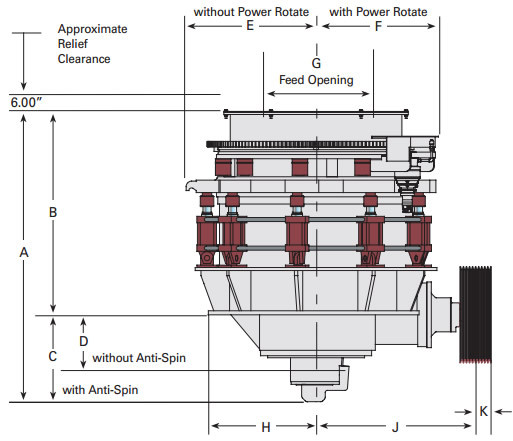

Working Principle

CS Series Cone Crusher is mainly composed of base assembly, eccentric sleeve assembly, transmission assembly, motor assembly, moving cone assembly, fixed cone assembly and so on. The auxiliary part consists of electrical system, lubrication system and so on.

Cone braking cone under eccentric set of leading role do rotary pendulum motion, crushing wall mounted between rolling mortar wall extrusion, rolling grinding materials, according to the theory of laminated material force by multiple directions, according to their own grain crushing and grinding, eventually to form stable stone particles, meet the requirements of the discharge from the broken wall spiral break down and the rest of the material to broken, Until the final requirements are met.

Product Parameter

| Model |

Movable Cone Diameter mm (inch) |

Chamber Style |

Opening Side |

Closed Side |

Discharging Opening (mm) |

REV (r/min) |

Power (kw) |

Motor Model |

Capacity (t/h) |

Machine Size (mm) |

| Max.Feeding (mm) |

| CSB75 |

900 (3′) |

Medium |

83 |

102 |

9-22 |

580 |

6-75 |

Y315S-6/75 |

45-91 |

2821×1880 ×2164 |

| Coarse |

159 |

175 |

13-38 |

59-163 |

| CSD75 |

914 (3′) |

Fine |

13 |

41 |

3-13 |

580 |

6-75 |

Y315S-6/75 |

27-90 |

2821×1880 ×2410 |

| Medium |

33 |

60 |

3-16 |

27-100 |

| Coarse |

51 |

76 |

6-19 |

65-140 |

| CSB160 |

1295 (4 1/4′) |

Fine |

109 |

137 |

13-31 |

485 |

6-185 |

Y355M2-6/185 |

109-181 |

2800×2342 ×2668 |

| Medium |

188 |

210 |

16-31 |

132-253 |

| Coarse |

216 |

241 |

19-51 |

172-349 |

| CSD160 |

1295 (4 1/4′) |

Fine |

29 |

64 |

3-16 |

485 |

6-160 |

Y355M1-6/160 |

36-163 |

2800×2342 ×2668 |

| Medium |

54 |

89 |

6-16 |

82-163 |

| Coarse |

70 |

105 |

10-25 |

109-227 |

| CSB240 |

1650 (5 1/2′) |

Fine |

188 |

209 |

16-38 |

485 |

6-240 |

|

181-327 |

3911×2870 ×3771 |

| Medium |

213 |

241 |

22-51 |

|

258-417 |

| Coarse |

241 |

268 |

25-64 |

|

299-635 |

| CSD240 |

1650 (5 1/2′) |

Fine |

35 |

70 |

5-13 |

485 |

6-240 |

|

90-209 |

3917×2870 ×3771 |

| Medium |

54 |

89 |

6-19 |

|

136-281 |

| Coarse |

98 |

133 |

10-25 |

|

190-336 |

| CSB400 |

2134 (7′) |

Fine |

253 |

278 |

19-38 |

435 |

6-400 |

|

381-726 |

5200×4300 ×4700 |

| Medium |

303 |

334 |

25-51 |

|

608-998 |

| Coarse |

334 |

369 |

31-64 |

|

870-1400 |

| CSD400 |

2134 (7′) |

Fine |

51 |

105 |

5-16 |

435 |

6-400 |

|

190-408 |

5200×4300 ×4700 |

| Medium |

95 |

133 |

10-19 |

|

354-508 |

| Coarse |

127 |

178 |

13-25 |

|

454-599

|

Note: This specification is just referencing, any changes are subject to the products.