European Coarse Powder Grinding Mill

Processing ability: 3-60 t/h

Fineness: 0-25 mm

Max feeding size: 400mm

Range of application: Calcium Carbonte、Limestone、Gypsum、Kaolin、Dolomite、Barite、Flourite...

- +8613917147829

- sales@clirik.com

Focus on the field of micro powder grinding !

Processing ability: 3-60 t/h

Fineness: 0-25 mm

Max feeding size: 400mm

Range of application: Calcium Carbonte、Limestone、Gypsum、Kaolin、Dolomite、Barite、Flourite...

Table of Contents

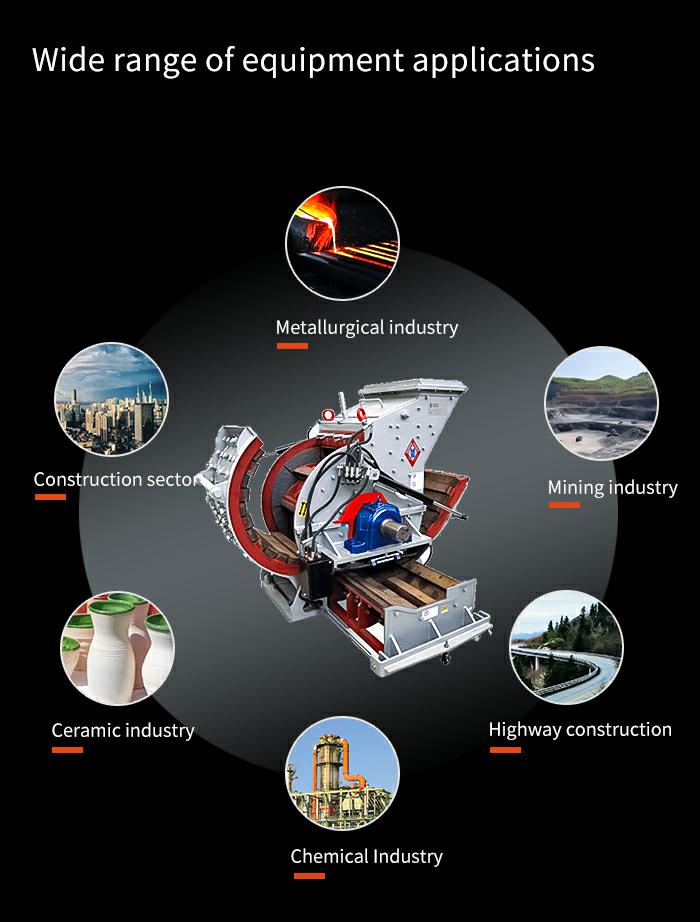

European coarse powder grinding mill is engaging in crushing various rocks and stones with comprehensive strength not higher than 320 MPa into coarse powder and small particles,it is widely used in metallurgy,mining,chemical,cement, coal,sand-making, coal gangue, construction , refractory materials and ceramic industries.

Product features of European coarse powder grinding mill :

1.Easy operation and low investment.

2.High capacity and lower power consumption.

3.Simple design and simple component replacement.

4.Uniform particle size with high crushing and crushing ratio

European coarse powder grinding mill mainly consists of frame, rotor, support iron and grate bars. The frame is divided into two parts: upper part and lower part, which are welded by steel plates after being cut. Liners made of high manganese steels within the frame can be replaced after being worn out. The rotors consist of turn plates, pin shafts, and hammers which are grouped regularly in the main shaft. The main unit drives the main shaft through the motor and triangle belts, which, in turn, rotates the rollers. Large materials entering the crusher through the feed inlet are firstly crushed by the high-speed hammers, and then thrown fiercely to the support iron for further crushing. Qualified materials crushed will be screened out and exit from the gap of the grate bars while the unqualified will be left in the crushing cavity to be further hammered and ground until reach the standard size. The size of the final product can be adjusted by changing the grate bars. The gap between the rotors and the grate bars can also be adjusted according to different requirement. To avoid the plugging of the crusher, the proportion of water for the crushing materials is no more than 20%.

|

Type |

PC400x300 |

PC600x400 |

PC800x600 |

|

Rotor Diameter /mm |

400 |

600 |

800 |

|

Rotor Width/ mm |

300 |

400 |

600 |

|

Rotor Speed/ r/min |

1100 |

1000 |

900 |

|

Max Feeding Size/mm |

<100 |

<220 |

<350 |

|

Finished particle size /mm |

0-10 |

0-20 |

0-22 |

|

Capacity / t/h |

3-8 |

8-15 |

15-45 |

|

Power /kw |

11 |

18.5-22 |

45 |

|

Hammer Number /pieces |

12-16 |

12-20 |

20-28 |

|

Dimension L*W*H/mm |

855*795*860 |

1150*1095*1230 |

2360*1490*1415 |

European coarse powder grinding mill operation guide:

1.The start of the European coarse powder grinding mill.

Before starting, the oil temperature in the mill must be preheated to 15℃ ~ 30℃, not more than 30℃.

(1) Check before startup.

Check whether all access doors are tightly closed, check whether bolts are loose, and ensure that all lubrication points are fully lubricated according to the lubrication system table and lubrication position chart.

(2) Startup sequence.

1. Start the analytical machine after the material is stored in the bin.

2. Start the centrifugal fan (start with empty load and load again after normal operation).

3. Start the host, in the complete start of the host can start electromagnetic vibration feeder. At this point, the grinding work begins.

The startup operation sequence is simply expressed as follows: Analysis machine → centrifugal fan → host machine → electromagnetic vibration feeder.

2.European coarse powder grinding mill shut down.

(1)The European coarse powder grinding mill shutdown precondition.

The operation of the equipment can be stopped only after all the materials on the equipment are processed and exported.

(2)European coarse powder grinding mill stop sequence.

When stopping, shut down the equipment in the forward direction of the production process, which is opposite to the starting sequence. The recommended stopping sequence is as follows:

1. Turn off the electromagnetic vibration feeder and stop feeding.

2. Stop the host after about one minute.

3. Stop the centrifugal fan after blowing the residual powder.

4. Shut down the analytical engine.

The shutdown sequence is: Electromagnetic vibration feeder → main engine → centrifugal fan → analysis machine.

Note!

The mill If any part of the European coarse powder grinding mill has abnormal noise, or the load suddenly increases, it should be stopped immediately for inspection and troubleshooting. If there is more material in the European coarse grinding mill, some material must be removed from the mill before starting the mill again. Otherwise, the starting current will be too large when starting the mill again, which will cause start-up difficulties and even burn the motor.

In addition to the European coarse powder grinding mill, our company also has many ultrafine powder equipment for you to choose.