Fine sand Aggregate Crushers – case in India

Raw Material: Aggregate

Country Of Client: India

Brief Introduction:

Production line of 600-700 tons per hour of Fine sand Aggregate in India, using Clirik Fine sand Aggregate Crushers

live chatFocus on the field of micro powder grinding !

Raw Material: Aggregate

Country Of Client: India

Brief Introduction:

Production line of 600-700 tons per hour of Fine sand Aggregate in India, using Clirik Fine sand Aggregate Crushers

live chatTable of Contents

Fine sand Aggregate Crushers – case in India

The Indian customer came to us through the website and he wanted to build a production line of 600-700 tons of fine sand aggregate per hour.

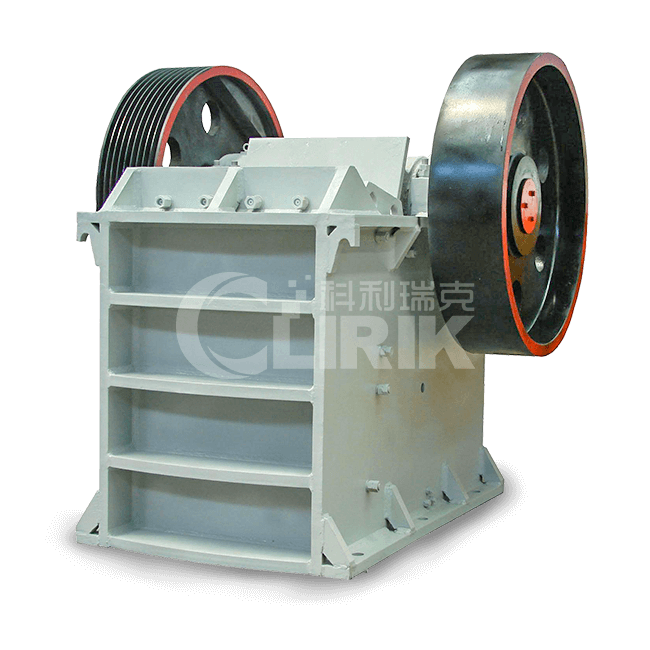

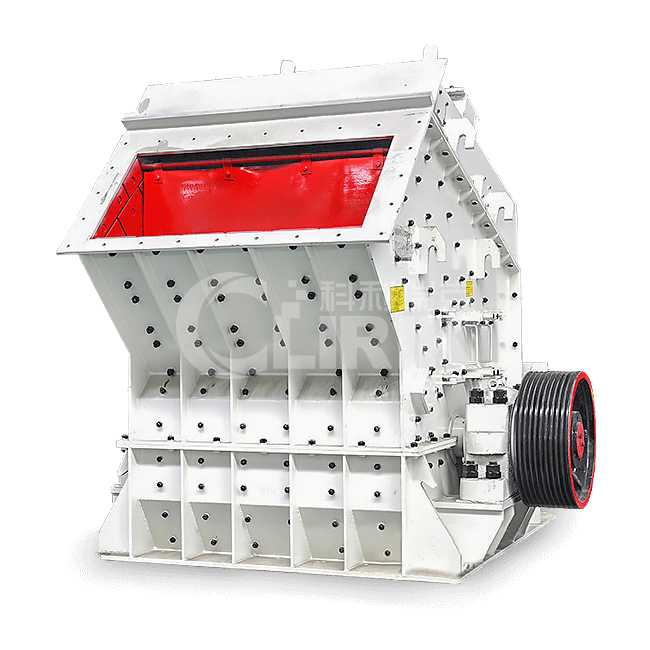

According to the detailed understanding of the material they want to process is construction waste , the finished product specification is 0-5-10-20-31.5mm. Therefore, we recommended fine sand Aggregate jaw crusher, impact crusher and feeder to him.

1. High efficiency, less equipment and low maintenance cost.

With less equipment for high speed and high efficiency crushing, save equipment maintenance costs.

2. Siemens energy-saving motor, low electricity cost, fast project return.

The average power cost per ton of stone is more than 2 yuan. The market for sand aggregate develops rapidly, the demand is large, and the project returns quickly.

3. It has environmental and social benefits.

The crusher is equipped with a manual or automatic grease lubrication system to reduce the difficulty of maintenance. It ensures the crusher operation site is clean and tidy to a large extent, and meets the requirements of environmental restoration and management projects while harvesting social benefits.

4. On-site professional service guarantee, fast delivery

Fast delivery, two months into production. Sebon technicians immediately rushed to the site to provide professional services to ensure production as scheduled.

Processing ability: 1-40 t/h

Fineness: 10-265 mm

Max feeding size: 125-850 mm

Range of application: Limestone, Calcite, Barite, Dolomite, Marble, Talcum, Gypsum, Kaolin…

Advantage: High crushing ratio, uniform particle size, fineness range of finished products can be adjusted, simple structure, convenient operation, safe and reliable, low operating cost.

Processing ability: 50-260 t/h

Fineness: 0-200 mm

Max feeding size: 350 mm

Range of application: Mica,Calcite、 Gypsum,Fluorite,Limestone, Soil,Clay,Calcium carbonate …

Advantage: Simplified crushing process, fineness of finished products can be adjusted, more suitable for crushing hard rock, high efficiency, low consumption.

Processing ability: 5-100 t/h

Max feeding size: 50-150 mm

Range of application: Metallurgy, Coal, Mineral Processing, Artificial Sand, Construction Waste Recycling, Building Materials, Chemical…

Advantage: Wide range of applicable materials, prevent dust pollution, less wearing parts, low vibration power consumption, significant energy saving.

In addition to the crushing production line, we have many ultrafine grinding production lines for your reference. You can consult us here for more details.