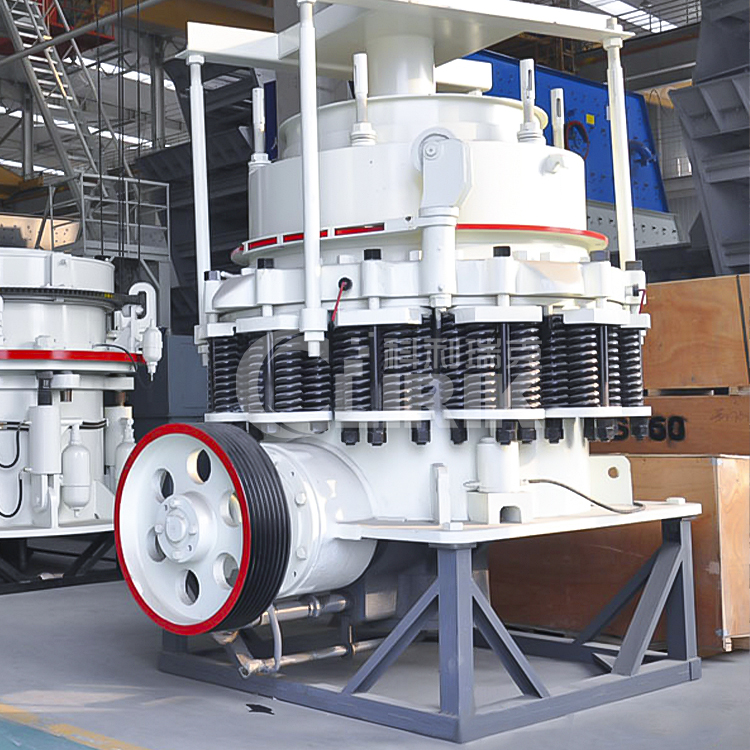

HCS Series Cone Crusher

Processing ability: 27-660 t/h

Fineness: 10-100 mm

Max feeding size: 275 mm

Range of application: Fluorite、Limestone、Soil、Clay、 Marble、 Granite、Pebble、Coal、Feldspar、Mica、 Calcite、 Gypsum...

- +8613917147829

- sales@clirik.com

Focus on the field of micro powder grinding !

Processing ability: 27-660 t/h

Fineness: 10-100 mm

Max feeding size: 275 mm

Range of application: Fluorite、Limestone、Soil、Clay、 Marble、 Granite、Pebble、Coal、Feldspar、Mica、 Calcite、 Gypsum...

HCS series cone crusher with hydraulic-driven system is a kind of new type high efficient crushing equipment which is developed by Clirik engineers through over 20 year’s effort of design, manufacture, sale, and after-sale service in crushing industries.

HCS series cone crusher is widely used in ores primary crushing, secondary crushing, tertiary crushing and fine crushing. such as quartz, feldspar, mica, calcite, gypsum, fluorite, limestone, soil, clay, marble, granite, pebbles, coal, slag, iron ore, copper ore, manganese ore, refractory materials, glass, etc. .

1. The new HCS Series Cone Crusher is safer and more stable in operation, convenient in maintenance, short in downtime and guaranteed in output, and is more suitable for large-scale sand and gravel production systems.

2. The HCS Series Cone Crusher adopts a multi-point split hydraulic lubrication control system, which has stronger bearing lubrication and overload protection capabilities, which greatly improves the automation of the entire production line.

3. The HCS Series Cone Crusher has re-experimentally designed the cavity type and stroke, which is more suitable for crushing hard materials such as river pebbles, basalt, iron ore, etc. The output is 35%-60% higher than that of ordinary spring cone crushers.

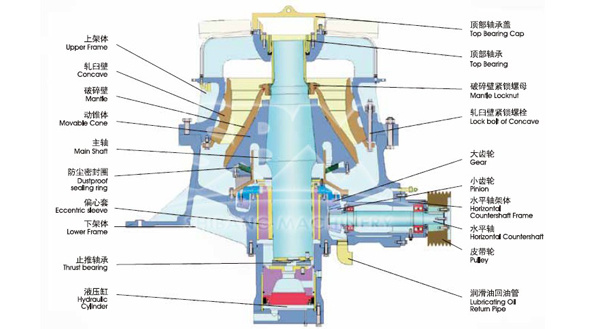

The HCS series cone crusher is driven by the eccentric sleeve to make a swinging motion, which drives the crushing wall to squeeze and grind the material between the crushing wall and the rolling mortar wall. According to the lamination theory, the material is subjected to forces in multiple directions, and according to its own texture After being broken and ground, stable stone particles will be formed, and those that meet the discharge requirements will fall from the swing gap of the crushing wall, and the rest of the materials will continue to be broken until the final requirements are met.

| Model | Movable Cone Diameter (mm) | Chamber Style | Max Feeding(mm) | Discharge Opening(mm) | Capacity(t/h) | Power(kw) | Machine Size(mm) |

| HCS100 | 790 | EC | 135 | 10-32 | 46-128 | 90 | 1550×1575×1965 |

| C | 90 | 10-25 | 43-118 | ||||

| M | 65 | 8-16 | 36-76 | ||||

| MF | 50 | 6-13 | 29-68 | ||||

| F | 35 | 4-10 | 27-57 | ||||

| EF | 28 | 6 | 30-40 | ||||

| HCS160 | 956 | EC | 180 | 13-38 | 69-215 | 160 | 1875×1920×2400 |

| C | 145 | 13-32 | 65-197 | ||||

| MC | 115 | 10-25 | 60-180 | ||||

| M | 90 | 10-22 | 60-160 | ||||

| MF | 75 | 8-19 | 61-125 | ||||

| F | 50 | 6-19 | 45-105 | ||||

| EF | 35 | 6 | 70-90 | ||||

| HCS250 | 1150 | EC | 215 | 16-44 | 110-380 | 250 | 2100×2320×2780 |

| C | 175 | 13-38 | 100-385 | ||||

| MC | 140 | 13-32 | 95-325 | ||||

| M | 110 | 13-25 | 115-335 | ||||

| MF | 85 | 10-22 | 90-280 | ||||

| F | 70 | 8-19 | 90-235 | ||||

| EF | 38 | 8 | 100-125 | ||||

| HCS315 | 1408 | EC | 275 | 16-44 | 177-660 | 315 | 2380×2735×3265 |

| CX | 245 | 16-38 | 170-650 | ||||

| C | 215 | 16-38 | 170-640 | ||||

| MC | 175 | 16-32 | 160-552 | ||||

| M | 135 | 16-32 | 195-500 | ||||

| MF | 115 | 13-32 | 190-450 | ||||

| F | 85 | 13-25 | 195-400 | ||||

| EF | 65 | 13-22 | 210-300 |

Note: This specification is just referencing, any changes are subject to the products.