How Is The Processing Of Limestone Processed?

Table of Contents

If you are interested in knowing how limestone is processed, this article will answer your questions about calcination, the sizes of particles, calcination temperatures, and hydrated lime production. Read on to learn more about this important mineral. It is used in construction materials, industrial processes, and in food and beverage production. There are several advantages and disadvantages to using limestone. In this article, you’ll learn more about the advantages of hydrated lime production.

Processes Involved

The basic chemistry of limestone is calcium, magnesium, iron, and silica. Calcium and magnesium are essential for glass making, while silica is mainly from sand. Iron is the primary impurity found in limestone, and glassmakers need to know what its effects might be before choosing a limestone for their process. Processes involved in processing limestone can be categorized as either wet or dry, depending on the purpose for which it is used.

Fuel is the next step in processing limestone. Fuel is used in rotary kilns. This fuel burns with the limestone in a kiln. The resulting carbon dioxide and quicklime are calcined. The carbon dioxide in the limestone reacts with impurities and forms an insoluble chemical called quicklime. The resulting quicklime is then used as a building material or as limestone powder.

Size Of Limestone Particles

The influence of particle size on impact velocity and crushing ratio in limestone was studied. The discrete element method is used to simulate viscous limestone particles. The simulation results show that particle size has significant effect on crushing ratio, and the maximum and minimum particle size are similar. There is a strong correlation between particle size and impact velocity, and there is a linear relationship between particle size and crushing ratio at 15 mm and above.

The effects of large volume and different particle size on mechanical and environmental properties of concrete were studied. The results show that large amount of limestone powder has positive effects on concrete strength and environmental performance, but particle size has no effect on the compressive strength of concrete. Conversely, smaller particle sizes can adversely affect the strength of concrete. In addition, the effect of limestone powder on concrete is not consistent throughout the particle size range.

Calcination Temperatures

There are several different considerations for calcination temperature in limestone processing.Limestone from the same quarry usually does not contain uniform composition. The difference in temperature and heating rate will also vary from kiln to kiln. However, higher temperatures allow greater production to be achieved in the same furnace area. Fixed losses remain constant, such as air infiltration into the chamber and radiation from the side walls. This high yield also improves fuel efficiency.

This process is highly endothermic and begins when the temperature exceeds the dissociation temperature. This temperature range is between 780℃ and 1340℃. In order to achieve the best combustion effect and reduce the accumulation in the kiln, the coal must be finely ground. The surface of the limestone stone begins to decompose at about 800℃. Occasionally, residual limestone blocks remain in the calcination zone, resulting in sintering.

Hydrated Lime Production

Hydrated lime is a mineral that is produced by the limestone processing industry. It is easily available around the world. However, the transportation costs of the product may add up to a significant portion of its value. Lime is a highly versatile mineral that is used for a variety of purposes.

The mineral comes in different forms, including powder and pulp. Typical hydrated lime passes through a 200-mesh sieve; However, more specific applications may require the use of 325-mesh screens. Limestone particles can be ground to a powder using a Clirik grinding mill.

Equipment Recommended

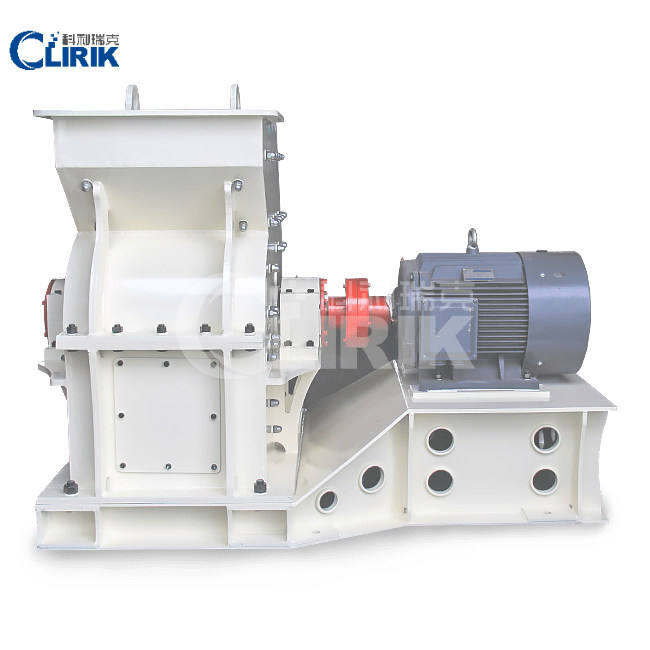

Grinding Mill

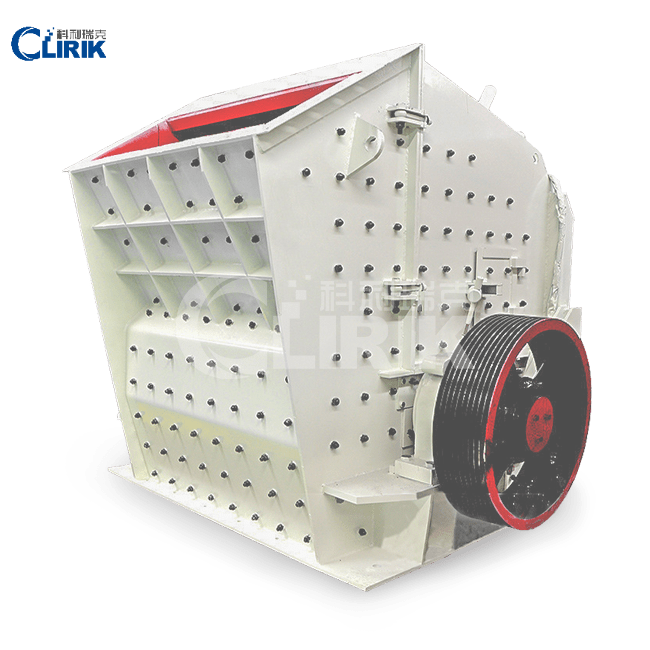

Crusher Mill