Installation site of HGM100 grinding mill in Uganda

Table of Contents

Installation site of HGM100 grinding mill

The video below is the installation site of the HGM100 grinding mill. From the video, we can see that the ring roller mill is a vertical mill with a small footprint and easy installation.

HGM series ultra-fine grinding mill can grind non-metallic ore with Mohs hardness less than 7, and the fineness can be adjusted flexibly.The HGM100 grinding mill has a small footprint, simple operation, high efficiency and energy saving, environmental protection and no pollution.

The customer’s grinding mill production line is mainly used for limestone powder processing.

About this customer

This customer in Uganda is processing limestone, and he needs to produce 500 mesh limestone, with an hourly output of more than 12 tons.

According to customer needs, we recommend the HGM100 grinding mill developed and produced by Clirik.This equipment can produce 150-3000 mesh limestone powder, and the fineness can be adjusted freely.

In addition, the ultrafine vertical grinding mill can also grind 100+ kinds of non-metallic ores, such as calcium carbonate, carbon black, calcite, mica, and so on.

Advantages of HGM100 grinding mill

In fact, our Raymond mill can also produce 500 mesh limestone, but the HGM series100 limestone ultrafine grinding mill can produce a larger range of powder fineness, up to 3000 mesh. This can help customers produce limestone of different specifications, respond to market demand and increase competitiveness.

More importantly, the maintenance of the ultra-fine vertical mill is very convenient. It does not need to be shut down for refueling, and it can be refueled for maintenance while working. Environmental protection is also much higher than that of Raymond Mill. Unless your material only needs to produce powder below 500 mesh, we recommend that you choose a more cost-effective ultrafine vertical mill.

Small footprint, low investment, high-cost performance.

Simple operation, intelligent control.

The fineness of the finished product is 150-3000 mesh, which can be adjusted freely.

Convenient maintenance, you can refuel while working, no need to shut down for maintenance.

Special wear-resistant alloy is used for wearing parts, which has a longer service life.

Energy-saving and environmental protection.

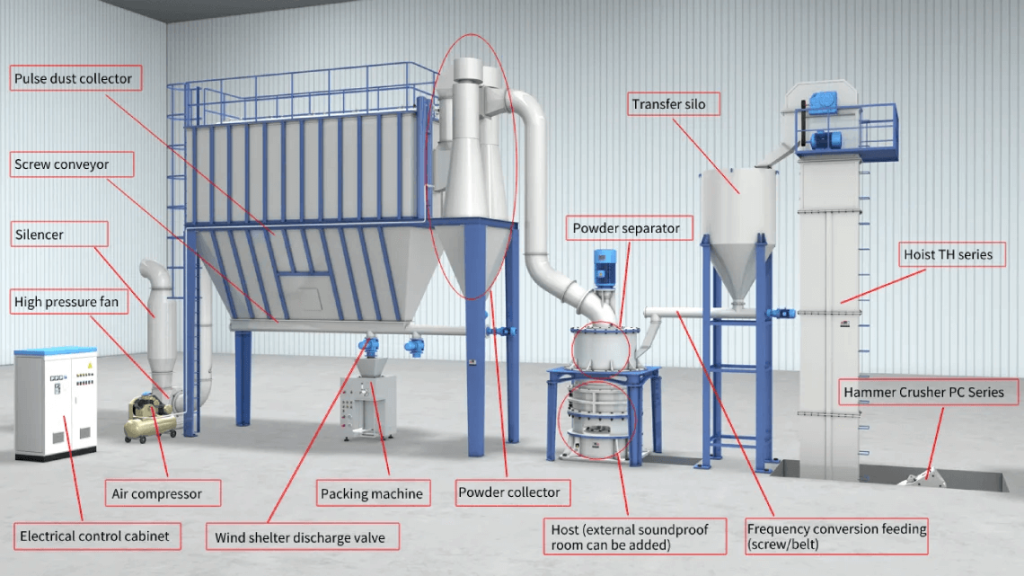

HGM100 grinding mill process of limestone

When the HGM100 grinding mill is at work, the main bearing and each dial are driven by electricity through reducer, and all the grinding rollers are rolling in the ring channels driving by dial through plunger.

The limestone materials are driven to the edge of the turn plate by the centrifugal force and fall down into the grinding chambers.

The high-pressure air blower constantly inhales air, airflow with crushed materials are brought to classifier whose high-speed impeller will screen the airflow: The unqualified particle size will fall and return to the mill for being around while the qualified particle size mixed with air will go into the cyclone powder collector.

Most of the qualified powders will fall and exit from the discharging valve at the bottom; a small proportion of the fine powders, with airflow, moves to the dust cleaner.

The materials from the above two lots are sent by the conveyor to get finished powders packed. In addition, filtered clean air will be emitted from muffler in the end.

In addition to the HGM series ultra-fine mills used by the above customers, our company also has CLRM series Raymond mills and YGM series high-pressure mills that can be used in the grinding process of limestone.

If you are interested in the limestone powder project, or you need to grind other non-metallic ores, you can directly leave us a message. We will reply to you within 24 hours.