Key application of diatomite in strategic emerging industries

Table of Contents

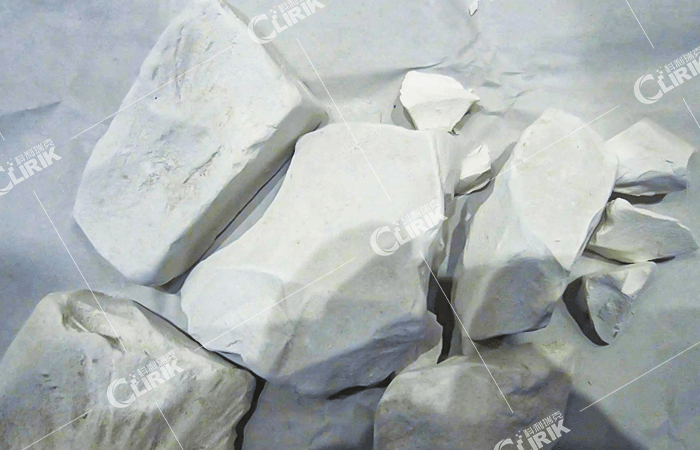

Diatomite is a siliceous rock formed hundreds of thousands of years ago by the remains of diatoms (” life-giving submarine steppe “).

Diatomite is well known to the public in daily life. Diatomite is often used as a wall decoration material. Place floor MATS in the kitchen and toilet where water is easy to accumulate; there are also beauty products commonly used by women, such as powder puffs, scrubs and talcum powder. But diatomite doesn’t stop there…

Properties and applications of diatomite

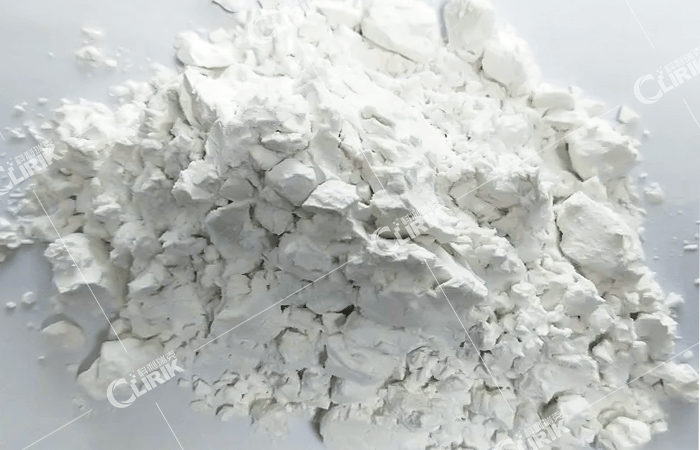

The chemical composition of diatomite is mainly amorphous SiO2, containing a small amount of Fe2O3, MgO, Al2O3, K2O and organic impurities.

Diatomite is usually white, off-white, light yellow or light gray, and the bulk density is 0.34~0.65g/cm3. Melting point 1650 ℃ ~ 1750 ℃; specific surface area 19~65cm2/ g; pore volume 0.45 ~ 0.98 cm/g; water absorption rate is 2 to 4 times its own volume. High chemical stability, insoluble in hydrochloric acid, easily soluble in alkali, physical properties with soft, sound insulation, wear resistance, heat resistance, water absorption and many other excellent performance.

According to the properties of the diatomite, by superfine grinding mill grinding of diatomite powder is used for filtering materials, insulation materials, functional fillers, building materials, catalyst carrier, and cement mixing materials such as products, as well as food, medicine, chemical industry, building materials, environmental protection, petroleum, metallurgy, papermaking, rubber, agriculture, animal husbandry and other industries. At present, there are more than 500 kinds of diatomite application products. With the development of technology and product upgrading, diatomite will be more widely used in emerging industries in the future.

Key applications in strategic emerging industries

New energy sector

In recent years, a great deal of research has been done on diatom materials and their composites with other nanomaterials, showing their great potential in the field of energy conversion and storage. This contains a wide range of energy-related areas such as lithium-ion battery materials, supercapacitors, solar cells, hydrogen storage properties and thermal energy storage. Scientists and engineers can take advantage of diatom of synthesize unique, versatile, three-dimensional silica structures, converting a low-cost biomaterial into a high-value material for energy production and storage applications.

New material field

Diatomite, with large specific surface area, appropriate pore volume and tiny pore size, is an ideal physical adsorption material for hydrogen storage at room temperature. The study of the specific porous microstructure of diatomite on the dehydrogenation performance opens up a new way to further improve the dehydrogenation performance of these devices.

Biomedical field

With the development of research, the porous structure of diatomite can maintain the amorphous form of therapeutic drugs, which is very important to improve the solubility and permeability of lipophilic drugs.

Diatomite has the characteristics of acid resistance, heat resistance, good biocompatibility, non-toxic side effects and so on. Its unique hollow porous microcapsule structure provides a larger specific surface area, so that it has a higher drug load, becoming an ideal choice for the development of nano drug carrier.

The SiO2 component of diatomite surfactant can be used as a graft point for various biomedical functionalization, which can effectively overcome the limitations of traditional drugs and be used for drug targeted delivery, hemostatic material development and tissue engineering.

The unique structure of diatomite has also inspired the design and production of new nanostructured materials that use its photonic properties for a variety of medical treatments, such as biosensing and micro-robots, expanding research on diatomite for biomedical applications.

Energy conservation and environmental protection field

Diatomite has the characteristics of large specific surface area, high porosity and multi-pore structure, and has excellent surface adsorption performance. Diatomite is widely used as filter aid in beer, pharmaceutical, water purification, sugar and other industries. Diatomite is used to adsorb heavy metal ions in industrial wastewater, and also to treat parking wastewater, printing and dyeing wastewater, municipal wastewater, pig slaughtering wastewater and so on. The new material prepared by nano-tio2 supported on diatomite matrix can be used to purify air in indoor louvers.

In other fields

Information technology: Diatomite is used in electronic packaging enclosures.

High-end manufacturing: for the production of aircraft thermal components.

Diatomite grinding products are recommended

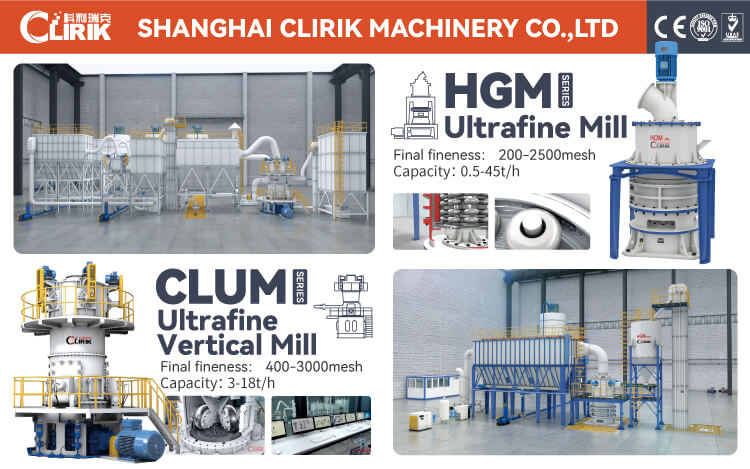

For grinding diatom powder, we recommend Clirik self-developed CLUM series ultrafine vertical powder grinding mill and HGM series micro powder grinding mill.