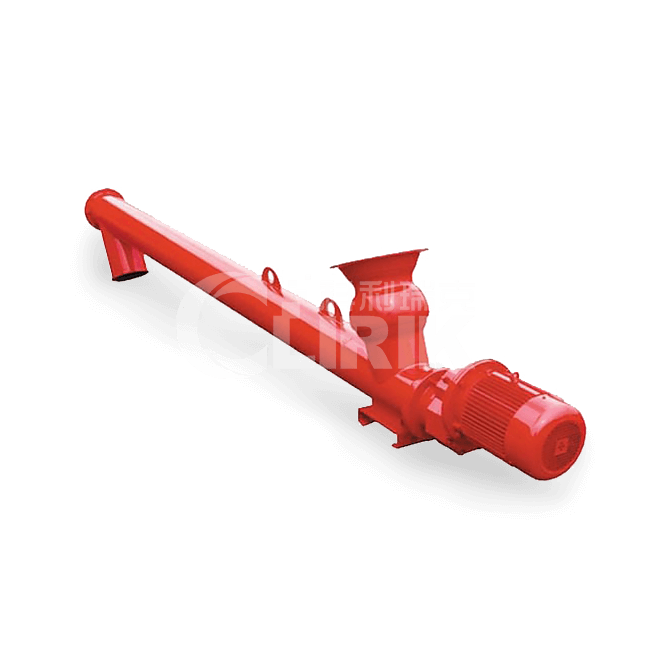

LS Screw Conveyor

Processing ability: 2-18 m³/ h

Fineness: /

Max feeding size: 250 mm

Range of application: Coal powder、Coal ash、Argil、Sand、 Cement、 Carbamide ...

- +8613917147829

- sales@clirik.com

Focus on the field of micro powder grinding !

Processing ability: 2-18 m³/ h

Fineness: /

Max feeding size: 250 mm

Range of application: Coal powder、Coal ash、Argil、Sand、 Cement、 Carbamide ...

LS screw conveyor is the updated model of the GX type screw conveyor. The whole conveyor is reliable, durable, adaptable, easy to install. It is suitable for conveying the powder, granular, and block materials (temperature <200℃),such as coal powder, coal ash, argil, sand, cement, carbamide etc. The screw conveyor is not only used for the concrete batching plant, bituminous concrete batching, but also for the chemical, building, food, metallurgy and so on.

1.Compared with GX type screw conveyor, Cement/Concrete Screw Conveyor eliminates the possibility of reducing bearing life because of untight seal and material leakage, as heading and rear bearings are removed outside the frame.

2. Simple structure, small floor space, low noise, good sealing, easy operation and maintenance.

3. High applicability, convenient feeding inlet and discharging outlet, easy for multi-point feeding and discharge materials.

LS screw conveyor of a shaft with a spiral blade and chute. The Shaft is installed at both ends of chute bearing base through bearing. The shaft head on one side of shaft connected with driving device. There are feeding inlet and discharging outlet on the top and bottom of chute.

LS screw conveyor Work steps :

Materials get into conveyor through feeding inlet. Subject to the reverse thrust of screw blade, the materials can rotate with shaft as for radial force of thrust and friction between blade and material.As a result of material itself gravity and friction between chute and materials, the materials do not rotate with spiral blade but move along the chute on the effect of axial thrust of blade radial thrust force. Materials move forward in spiral form, that is moving forward accompanied with tumbling motion in circumferential direction.

|

Model |

LS159 |

LS219 |

LS250 |

|

|

Diameter(mm) |

159 |

219 |

250 |

|

|

Screw pitch (mm) |

159 |

219 |

250 |

|

|

Rotate speed (r/min) |

83 |

83 |

90 |

71 |

|

Conveying Capacity (m³ /h) |

2-6 |

5-12 |

22 |

18 |