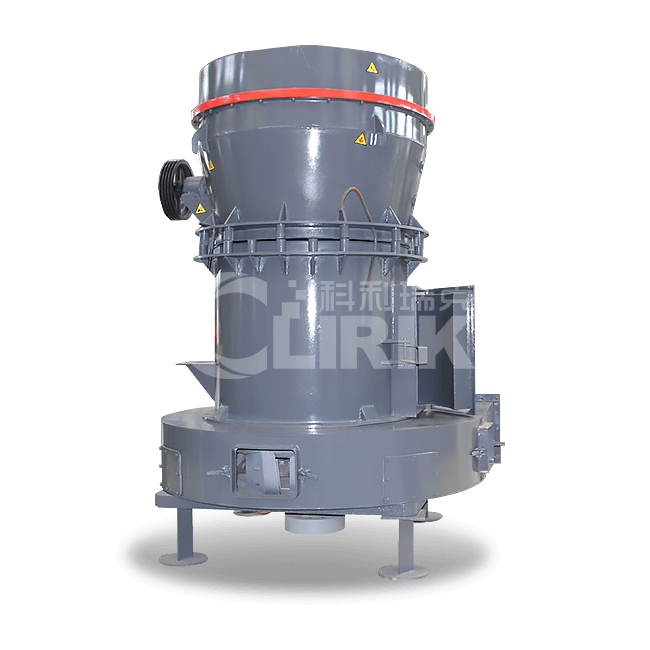

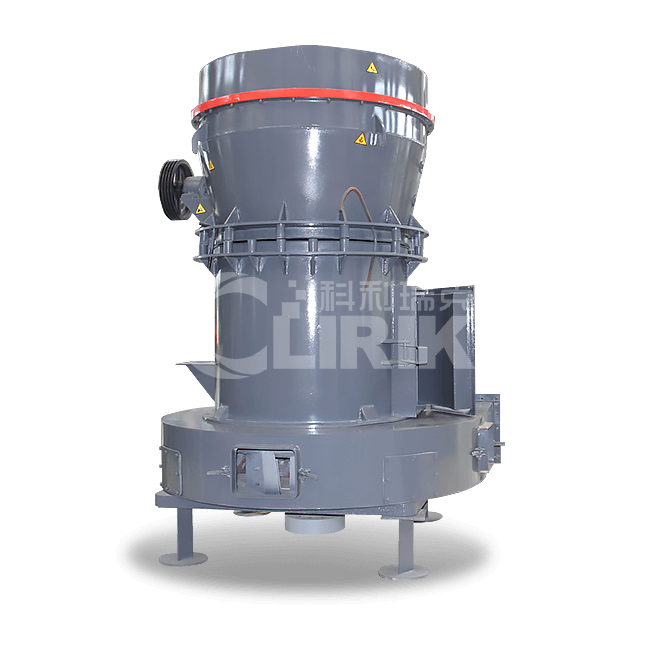

Product Introduction Of Mica Powder Raymond Mill

Mica powder Raymond mill is a type of mill commonly used in the mica processing industry for grinding and processing mica into various powders. Raymond mill is known for its advanced structure, stable performance, and efficiency in grinding different materials.

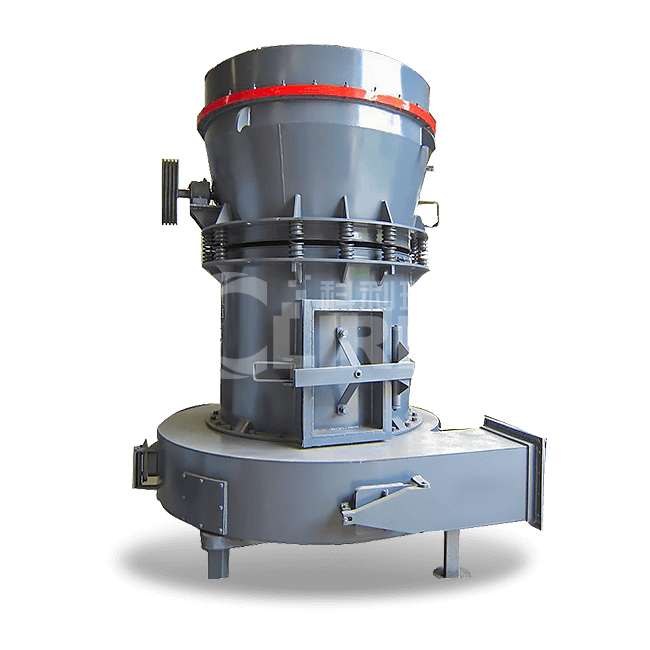

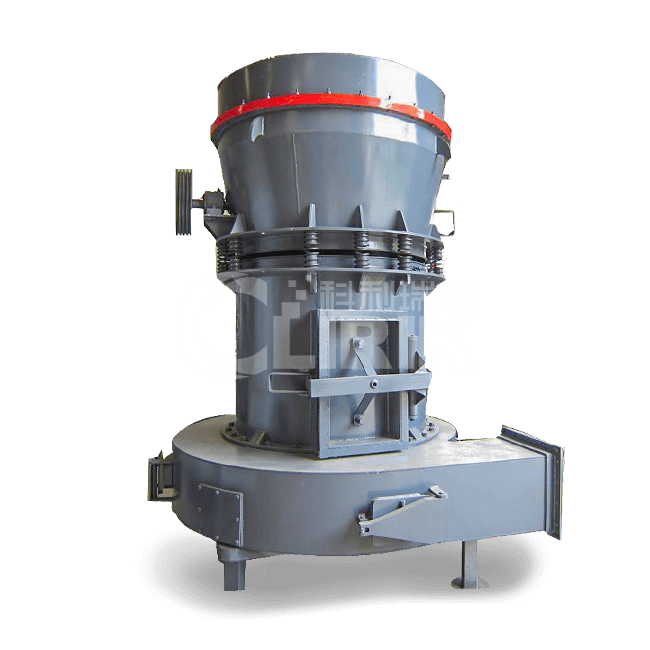

Brief overview of mica powder Raymond mill working:

Grinding Process: Mica is fed into the machine through the feeder and is ground by the grinding roller and grinding ring.

Airflow Selection: The airflow from the fan enters the grinding chamber, and the qualified mica powder is collected by the dust collector.

Product Collection: The finished mica powder is separated from the airflow and collected in the powder collector. The coarse particles are returned to the grinding chamber for further grinding.

Control System: The entire process is controlled by the electrical system, ensuring stable operation and precise control of the grinding process.

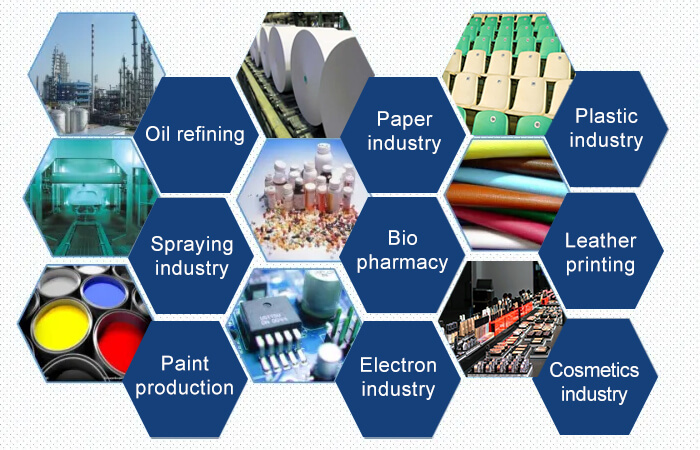

Product Application Of Mica Powder Raymond Mill

The application of mica powder produced by Raymond mill is diverse and finds use in various industries. Here are some common applications of mica powder:

1. Cosmetics Industry: Mica powder is widely used in cosmetics for its shimmering and reflective properties. It is a common ingredient in eyeshadows, blushes, lipsticks, and other makeup products to add a glittering effect.

2. Plastics Industry: Mica powder is incorporated into plastics to enhance their mechanical and thermal properties. It improves the strength, stiffness, and heat resistance of plastic materials.

3. Rubber Industry: Mica powder is used as a reinforcing filler in rubber products, providing improved strength, elasticity, and heat resistance.

4. Coatings and Paints: Mica powder is utilized in coatings and paints to enhance the texture, durability, and resistance to weathering. It also contributes to the reflective properties of certain coatings.

5. Electrical Insulation: Due to its electrical insulating properties, mica powder is used in the electrical and electronics industry. It is employed in the manufacturing of insulating materials for electrical components.

6. Construction Materials: Mica powder can be added to construction materials such as concrete, mortar, and plaster to improve their workability, strength, and resistance to cracking.

7. Oil Well Drilling: Mica powder is used as a lubricant and filtering agent in the oil well drilling industry. It helps in preventing the clogging of drilling equipment.

8. Plasterboard and Wallboard: Mica powder can be incorporated into plasterboard and wallboard to improve their fire resistance and insulation properties.

9. Personal Care Products: Apart from cosmetics, mica powder is also used in various personal care products like lotions and soaps for its aesthetic appeal.

10. Automotive Industry: Mica powder finds applications in automotive components, providing heat resistance and reinforcement in materials used for various parts.

Product parameter of Mica powder Raymond mill

| Model |

Roller |

Ring |

Feeding

Size(mm) |

Finished

Size(mm) |

Mill System

Power(KW) |

Capacity

(t/h) |

Overall

Dimension (mm) |

Quantity

(piece) |

Diameter

(mm) |

Height

(mm) |

Inner

Diameter

(mm) |

Height

(mm) |

| YGM7815 |

3 |

260 |

150 |

780 |

150 |

15 |

0.613-0.033 |

35.7 |

1.0-3.0 |

4300*3500*5100 |

| YGM9517 |

4 |

310 |

170 |

950 |

170 |

25 |

0.613-0.033 |

72.65 |

2.1-5.6 |

7100*5900*7900 |

| YGM1280 |

3 |

370 |

240 |

1170 |

240 |

20 |

0.613-0.033 |

145.15 |

4.5-12.0 |

9300*5600*8200 |

| YGM1300 |

4 |

410 |

280 |

1270 |

280 |

20 |

0.613-0.033 |

202.15 |

6.5-16.0 |

9100*8200*8400 |

| YGM1620 |

4 |

450 |

300 |

1500 |

300 |

20 |

0.613-0.033 |

322.2 |

8.0-20.0 |

12500*5700*10500 |

| YGM1720 |

4 |

510 |

300 |

1720 |

300 |

35 |

0.613-0.033 |

450 |

10.5-28.0 |

11550*9500*1050 |