Mineral Powder Grinding Mill in Turkey

Raw Material: Limestone and calcite

Country Of Client: Turkey

Brief Introduction:

High quality mineral powder grinding mill in Turkey.

live chatFocus on the field of micro powder grinding !

Raw Material: Limestone and calcite

Country Of Client: Turkey

Brief Introduction:

High quality mineral powder grinding mill in Turkey.

live chatTable of Contents

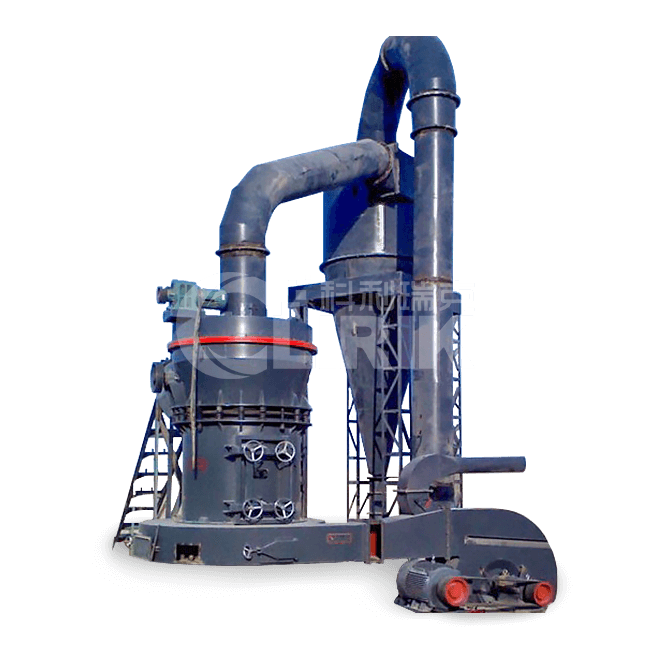

This customer need grinding mill for making mineral powder. The main ingredient of his mineral is limestone and calcite, and the required discharge size is 600mesh, and we recommend HGM superfine grinding machine to him. It can decrease energy consumption by 30% than other common grinding equipments.

In addition to limestone and calcite, HGM series mineral powder grinding mill can also handle other minerals, such as common minerals: kaolin, bentonite, marble, gypsum, quartz, feldspar, clay, talc, fluorite, clay, white, mud, mica and so on. There are some uncommon minerals, such as cordierite, skarn, serpentinite, phyllite etc.. If we calculate the quantity of it, the material type can be up to 1000 kinds.

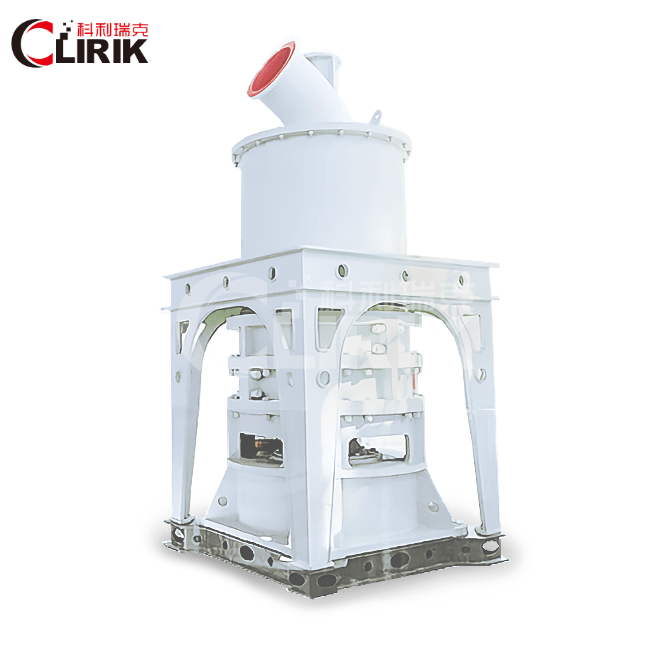

Mineral powder grinding mill is a machine used to grind minerals into powder form. It is used in various industries like mining, metallurgy, cement, ceramics, etc. Here are some characteristics of mineral powder grinding mill:

1. High efficiency

Mineral powder grinding mill is designed with high efficiency in mind. It can grind materials to the required fineness with minimum energy consumption.

2. Large capacity

Mineral powder grinding mill can process large quantities of material in a single operation. This is important for industries that require high production rates.

3. Wide range of applications

Mineral powder grinding mill can be used to grind a wide range of minerals, including limestone, gypsum, coal, barite, calcite, and many others.

4. Adjustable fineness

Mineral powder grinding mill can be adjusted to produce different fineness levels, depending on the needs of the application.

5. Easy maintenance

Mineral powder grinding mill is designed for easy maintenance and repair. Its parts are easy to replace, and it is designed for long-term use.

6. Environmentally friendly

Mineral powder grinding mill is designed to minimize environmental impact. It uses energy-efficient motors and produces minimal noise and dust.

Maintaining a mineral powder grinding mill is important to ensure its longevity and efficiency. Here are some tips to help you maintain your mineral powder grinding mill:

1. Regularly inspect and clean the grinding mill.

2. Lubricate the bearings and other moving parts.

3. Check the grinding media regularly.

4. Monitor the mill’s performance.

5. Conduct regular maintenance checks.

By following these tips, you can ensure that your mineral powder grinding mill is maintained properly and continues to perform efficiently for many years to come.

In addition to HGM series ultrafine powder grinding mill, we have many other series of grinding machines for you to choose, you can tell us your needs, our sales manager will give you reasonable suggestions.