PC Series Hammer Crusher

Processing ability: 5-30 t/h

Fineness: 0-25 mm

Max feeding size: <350 mm

Range of application: Calcium Carbonate、Limestone、Kaolin、Mica、Calcite...

- +8613917147829

- sales@clirik.com

Focus on the field of micro powder grinding !

Processing ability: 5-30 t/h

Fineness: 0-25 mm

Max feeding size: <350 mm

Range of application: Calcium Carbonate、Limestone、Kaolin、Mica、Calcite...

Table of Contents

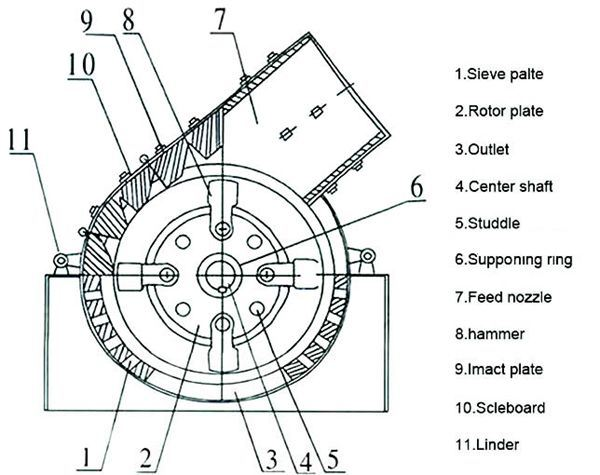

PC Series Hammer Crusher is engaging in crushing various rocks and stones with comprehensive strength not higher than 320 MPa into fine and micro fine powders, is widely used in metallurgy, mining, chemical, cement, coal, sand-making, coal gangue, construction, refractory materials and ceramic industries.

High capacity,high crushing ratio

Low power consumption,uniform particle size

The mechanical structure is simple, compact and light

Low investment ,easy management and maintenance

PC Series Hammer Crusher the motor drives the rotor to rotate at a high speed through the belt, and on the rotor there are series of hammers. When the materials get into the working area of hammers, the rotating hammers with high rotation speed are crushing them. The crushed products meeting the required size can be discharged by the outlet and become the final products, while the large size products are brought back to the crushing area by the hammers for being re-crushed until they reached the required size.

Product specification of PC Series Hammer Crusher:

| Model | PC400x300 | PC600x400 | PC800x600 |

| Rotor Diameter (mm) | 400 | 600 | 800 |

| Rotor Length (mm) | 300 | 400 | 600 |

| Rotor Speed(r/min) | 1100 | 1000 | 900 |

| Max. Feeding Size(mm) | <100 | <220 | <350 |

| Ouput Size(mm) | 5-10 | 5-15 | 5-20 |

| Capacity(t/h) | 5-13 | 10-20 | 18-30 |

| Motor Power(kw) | 11 | 18.5 | 45 |

| Moisture of feeding material | <3% | <3% | <3% |

| Number of Hammer(piece) | 16 | 20 | 28 |

| Weight(t) | 0.8 | 1.8 | 2.8 |

| Overall Dimension (L*W*H/mm) | 900*670*860 | 1200*1050*1200 | 2360*1490*1415 |

| Note: This specification is just referencing, any changes are subject to the products. | |||

(1) The oil quantity of PC Series Hammer Crusher main bearing and other transmission parts should be checked in detail before starting the machine, and enough lubricating oil should be added. It needs to run empty for 20-30 minutes for the first time, and then add appropriate lubricating oil.

(2) Check whether PC Series Hammer Crusher the connecting screws of each part are loose or broken.

(3) Check whether PC Series Hammer Crusher there are obstacles in the body and each transmission part.

(4) Check whether PC Series Hammer Crusher transmission device and motor are normal, such as whether there is a broken layer of the belt, whether the motor junction box and grounding device are firmly connected, and whether the protective device of the transmission mechanism is intact.

Only after the inspection of the above components is normal can the startup signal be given, and then the device is started in sequence.

(1) PC Series Hammer Crusher can start feeding after normal operation.

(2) The crushed material must be evenly added and distributed on the full length of the rotor working part to prevent the motor load surge.

(3) regularly checkPC Series Hammer Crusher sieve plate, if there is a blockage that should be removed immediately.

(4) Under normal working conditions, PC Series Hammer Crusher temperature rise of the bearing should be controlled in the range of 35 ℃ , and the temperature should not exceed 70 ℃ (if it exceeds the time to stop, find out the reason to eliminate it.)

(5) Stop printing before stopping the feeding work, until all the material in the PC Series Hammer Crusher is broken, the motor can be turned off.

(6) The PC Series Hammer Crusher adjustment of product fineness can be achieved by the following three methods:

1.Replace the screen style, or in the screen and the two ends of the screen frame groove embedded in the liner to change the screen gap.

2.Replace the extended hammer head to adjust the gap between the hammer and the screen strip.

3.Improve the speed of the rotor.

(7) When the amount of vibration suddenly increases, it should be stopped immediately to find out the reason to eliminate.

(8) The PC Series Hammer Crusher impact part of the hammer on one side of wear, can be reversed on the other side of the use, assembly or replacement of the hammer, must maintain the balance of the rotor. The total AMOUNT OF 6 hammers ON EACH HAMMER shaft shall be equal to the total amount of hammers on the opposite hammer shaft, with a total deviation of more than 100 grams.

(1) In the normal operation of the PC Series Hammer Crusher, in case of sudden shutdown, can not be forced to start the equipment before checking the reason, the reason is identified, to blow the crusher material to clean out, can be started in order.

(2) Pay attention to whether the sound is normal in the operation of the PC Series Hammer Crusher. When there is abnormal sound such as hammerhead and sieve plate, edge guard plate beating, friction and so on, it should be dealt with in time. It is strictly prohibited to inspect the operating equipment.

(3) After the PC Series Hammer Crusher is shut down, the wear of the hammer head, lining plate and discharging sieve plate should also be checked.

(4) It should be noted that the rotation of the rotor (marked with a rotation arrow on the belt wheel) is irreversible.

(5) According to the installation situation, the transmission belt protection cover should be equipped.

PC Series Hammer Crusher manufacturer introduction:

Shanghai Clirik Machinery Co., Ltd. has a professional technical force and perfect production capacity. The company’s products are widely used in mining, road construction, bridge construction, housing construction and other industries, mill, crusher, modified machine, ball mill, feeder, vibrating screen, sand washing machine, conveyor and other equipment and products. All passed ISO9001:2008 standard quality certification.

This is the customer’s visit to our factory. You can visit our company in both online and offline ways. If you need, you can leave your contact information and let our sales manager arrange a visit to the factory for you.

Purchase PC Series Hammer Crusher, we can provide you with the following services.

Pre-sale service:

1.Clirik provides a variety of mining equipment for you to choose from.

2.Clirik will recommend suitable production lines and grinding equipment to you according to your site.

3.Clirik customizes the logo and color of the grinding equipment according to your company image.

4.Clirik provides third party inspection to ensure the quality of your grinding equipment.

After-sales service:

1.Clirik provides you with online installation and uses videos.

2.Clirik will provide you with technicians to install and debug the grinding equipment.

3.Clirik trains you the technicians who use and maintain the grinding equipment.

4.Click provides you with a one-year warranty and lifetime service for grinding equipment.

More than 30 years of experience.

We are the leading professional supplier of mining machinery, construction machinery, machines casting and forged parts.

All products achieved ISO9901:2008 quality management certificate and CE, ROHS certificates.

Parts lead time 1-2months, machines 2-3 months.

Accept payment type: T/T, L/C, Western union, Cash.

30% deposit when signed the contract.

Full payment paid before shipping.

Guarantee time: one year for main machinery.

If something is wrong, we will provide technical advice and find a solution immediately. For those wearing parts, we guarantee high quality parts for long-term supply.