Quartz Powder Grinding Mill in Sri Lanka

Raw Material:

Country Of Client:

Brief Introduction:

Clirik high quality quartz powder grinding mill in Sri Lanka

live chatFocus on the field of micro powder grinding !

Raw Material:

Country Of Client:

Brief Introduction:

Clirik high quality quartz powder grinding mill in Sri Lanka

live chatTable of Contents

Product: HGM Quartz Powder Grinding Mill

Material: Quartz

Feeding Size: 10mm

Discharging Size: 1250mesh(10um) Country of customer: Sri Lank

Product: HGM Quartz Powder Grinding Mill

Material: Quartz

Feeding Size: 10mm

Discharging Size: 1250mesh(10um) Country of customer: Sri Lank

Quartz powder grinding mill is a specialized equipment designed to grind quartz or silica minerals into fine powder particles. Quartz is a crystalline mineral of silicon dioxide, commonly found in igneous, metamorphic, and sedimentary rocks. The grinding mill is employed to process raw quartz to obtain the desired particle size distribution for various industrial applications.

1. Particle size control

The main goal of a quartz powder grinder is to achieve a specific particle size distribution. Different industries may require different sizes of quartz powder, and the grinder will be adjusted accordingly to meet these specifications.

2.Material Processing

This grinder is designed to handle the hardness and abrasiveness of quartz. The coarse quartz is fed into a mill where it is ground to reduce it to the desired particle size. The ground quartz powder is then collected for further processing or use.

3. Applications

The resulting quartz powder has a variety of industrial applications. It is commonly used in the production of glass, ceramics, building materials, electronics and other industries, where the properties of quartz contribute to the quality and performance of the final product.

4. Precision and efficiency

The quartz powder mill is equipped with advanced technology to ensure grinding accuracy and processing efficiency. This includes features such as automated controls, advanced materials for grinding elements, and optimized operating parameters.

5. Versatility

While the primary focus is on grinding quartz, many mills have the versatility to process other minerals or materials, providing flexibility for different industries and applications.

6. Quality and Consistency.

Reliable quartz powder grinders ensure that the output powder always meets quality standards. For industries that rely on quartz powder as a raw material, consistency in particle size and other properties is critical.

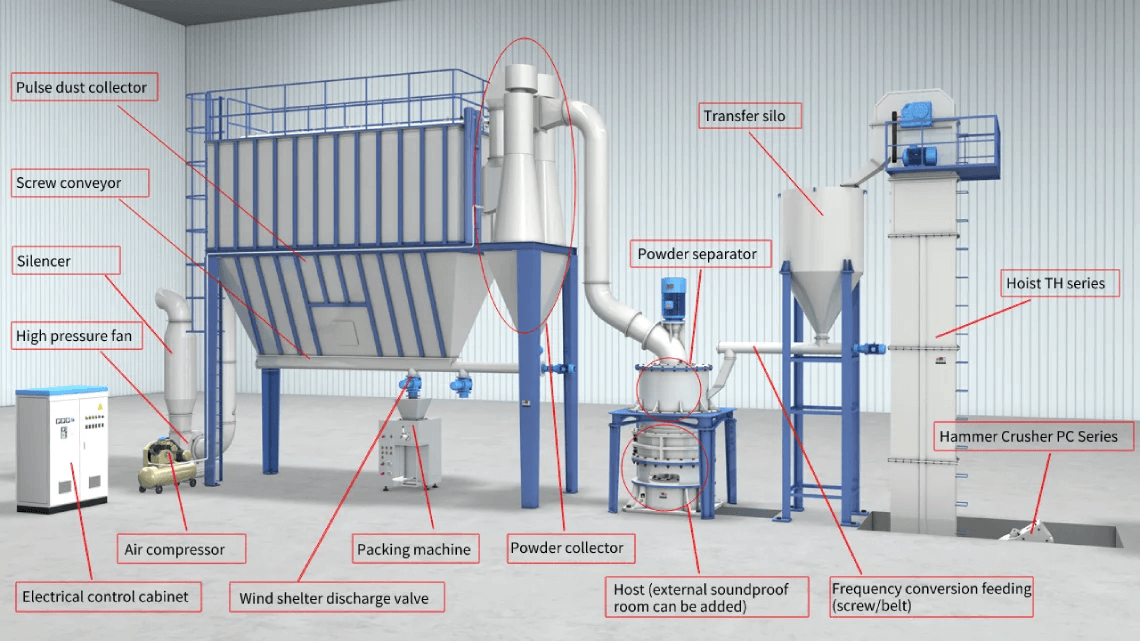

Quartz powder grinding mill mainly consist of main unit, classifier, powder collector, dust cleaner, blower, muffler, sound-proof room, crusher, bucket elevator, storage hopper, and vibrating feeder.

After crushed by hammer crusher, the large materials become small ones and are sent to storage hopper by elevator, and then evenly sent to the upper distribution plate of the turn plate by vibrating feeder and sloping feeding pipe. When the grinding mill is at work, the main bearing and each dial are driven by electromotor through reducer, and all the grinding rollers are rolling in the ring channels driving by dial through plunger. The materials are driven to the edge of the turn plate by the centrifugal force and fall down into the grinding chambers. The high-pressure air blower constantly inhales air, airflow with crushed materials are brought to classifier whose high-speed impeller will screen the airflow: The unqualified particle size will fall and return to the mill for being reground while the qualified particle size mixed with air will go into the cyclone powder collector. Most of the qualified powders will fall and exit from the discharging valve at the bottom; A small proportion of the fine powders, with airflow, moves to the dust cleaner. The materials from the above two lots are sent by the conveyor to get finished powders packed. In addition, filtered clean air will be emitted from muffler in the end.