YGM Series High Pressure Suspension Grinding Mill

Processing ability: 1-30t/h

Fineness: 50-325 mesh

Max feeding size: 20mm

Range of application: Calcium Carbonate 、Limestone 、Kaolin、Gypsum 、Bentonite、Dolomite...

- +8613917147829

- sales@clirik.com

Focus on the field of micro powder grinding !

Processing ability: 1-30t/h

Fineness: 50-325 mesh

Max feeding size: 20mm

Range of application: Calcium Carbonate 、Limestone 、Kaolin、Gypsum 、Bentonite、Dolomite...

Product Overview

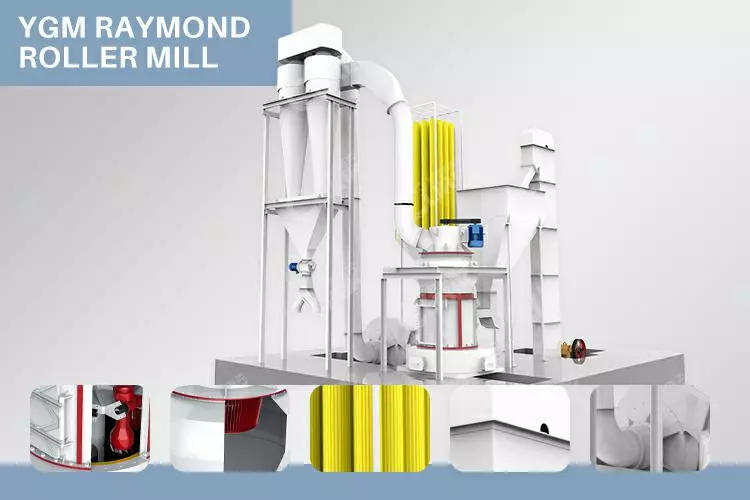

YGM Series High Pressure Suspension Grinding Mill for sale is mainly composed of main unit, analyzer, fan, dischargeing cyclone separator, powder cyclone separator and air duct. Among them, the main unit consists of frame, blow shell, shovel, grinding roller and grinding ring.

Product Application

YGM Series High Pressure Suspension Grinding Mill is the new type Raymond mill of our company, which is suitable for processing various non-flammable and non-explosive mineral materials with Moh’s hardness less than 6 and humidity less than 6%. It is widely used in the fields of metallurgy, construction, chemical industry, mining, highway construction etc,. The granularity of the finished powder size can be adjusted between 30 and 425 mesh. Examples of processing materials include quartz, feldspar, barite, calcite carbonate, limestone, talc, ceramic, iron ore, carborundum, bauxite, rock phosphate, coal and other materials, about 400 kinds of materials in total.

Product Specifications

Product parameter of YGM series high pressure suspension grinding mill

| Model | Roller | Ring | Feeding Size(mm) |

Finished Size(mm) |

Mill System Power(KW) |

Capacity (t/h) |

Overall Dimension (mm) |

|||

| Quantity (piece) |

Diameter (mm) |

Height (mm) |

Inner Diameter (mm) |

Height (mm) |

||||||

| YGM7815 | 3 | 260 | 150 | 780 | 150 | 15 | 0.613-0.033 | 35.7 | 1.0-3.0 | 4300*3500*5100 |

| YGM9517 | 4 | 310 | 170 | 950 | 170 | 25 | 0.613-0.033 | 72.65 | 2.1-5.6 | 7100*5900*7900 |

| YGM1280 | 3 | 370 | 240 | 1170 | 240 | 20 | 0.613-0.033 | 145.15 | 4.5-12.0 | 9300*5600*8200 |

| YGM1300 | 4 | 410 | 280 | 1270 | 280 | 20 | 0.613-0.033 | 202.15 | 6.5-16.0 | 9100*8200*8400 |

| YGM1620 | 4 | 450 | 300 | 1500 | 300 | 20 | 0.613-0.033 | 322.2 | 8.0-20.0 | 12500*5700*10500 |

| YGM1720 | 4 | 510 | 300 | 1720 | 300 | 35 | 0.613-0.033 | 450 | 10.5-28.0 | 11550*9500*1050 |

Working Principle

YGM Series High Pressure Suspension Grinding Mill grinds big materials, it needs to use a crusher to grind the materials to the required particle sizes, and carried by bucket elevator to the storage hopper, and are fed evenly and continuously by vibrating feeder into the main unit for grinding. The grinded powder are carried by the airflow from the blower to the classifier to be classified, the particles which meet the fineness enter cyclone collector through pipe, and are separated and collected there. They are discharged at the discharging valve to become finished products; The airflow is sucked to the blower by return pipe on the top of cyclone collector. The whole airflow system is a sealed circulation, and is circulated under positive and negative air pressure.

1.The equipment is mature and stable.

Nearly 30 years of experience in grinding and designing different materials, mature transformation of YGM series high pressure suspension grinding mill.

2. High efficiency, large output.

YGM series high pressure suspension grinding mill Breaking through the bottleneck of traditional pendulum mill production capacity, enjoy the advantages of large single production capacity at home and abroad, single processing capacity up to 50T/H, under the same power, the output is 20% higher than the traditional mill, 30% higher than the ball mill.

3.Reliable technology and low operating cost.

New technology, China’s national patent products, with technical innovation to create a three-dimensional structure, small footprint, strong system, from raw material rough processing, transportation, milling, to the final packaging, can become an independent production system barite powder Raymond mill.

Special grinding roller and grinding ring structure design, improve grinding efficiency, use cost reduction. The volute adopts the layout of no resistance and the same resistance, which greatly reduces the power and energy loss caused by the system energy consumption.

4. Multi-purpose, investment economy.

Without replacing any parts, one device is used for different materials and different finished particle size requirements.

Under the same output, the investment amount is only half of the ball mill, and the floor area is only one third of YGM Series High Pressure Suspension Grinding Mill. The infrastructure construction cost of the factory is low, the investment is economical, the capital recovery is quick, and the profit is quick.

5.Energy conservation and environmental protection.

YGM Series High Pressure Suspension Grinding Mill Small dust discharge, special dust collector configuration, dust removal effect of 99.99% or more, basically realize workshop dust-free operation.

Low operating noise, machine vibration is small, the noise is 20-30 decibels lower than the ball mill.

SHANGHAI CLIRIK MACHINERY CO., LTD located in PUDONG New district of Shanghai China as a professional enterprise, which specializes in research, manufacture and sales of all kinds of mining equipment. Our company has already formed a full set of modern production lines, equipped with intelligent, standardized testing and controlling laboratories, owned a professional team for R&D, production, sales and service.

So far, we have established a whole production chain, the products cover micro powder grinding mill, YGM series high pressure suspension grinding mill, European coarse powder grinding mill , hammer crusher, jaw crusher, screw conveyor, bucket elevator and so on. They are widely used in the industry of mining, construction materials, chemicals, metallurgy, transportation, hydraulic engineering and so on.

Especially we independently developed HGM micro powder grinding mill, which are not only renowned in the domestic market, but also have been sold widely in Eastern Europe, Middle East, Africa, South Asia, Southeast Asia, Oceania, and America, etc.We still insist on communication and cooperation with prestigious scientific research institutions from both home and abroad to make our development ability always on the domestic front.

Based on the principle of constant innovation and quality guarantee, customer foremost, we are able to provide our customers not only the highest quality products at the most favorable price but also the most reasonable solution, such as the selection of the equipment, optimized process configuration and a full range of technical support. Therefore, we always follow your steps, pursue your value and achieve your benefit.