Roller Shell

Processing ability: /

Fineness: /

Max feeding size: /

Range of application: Ultrafine Vertical Powder Grinding Mill

- +8613917147829

- sales@clirik.com

Focus on the field of micro powder grinding !

Processing ability: /

Fineness: /

Max feeding size: /

Range of application: Ultrafine Vertical Powder Grinding Mill

Table of Contents

Roller Shell

Model: LM, CLUM, ZGM, HRM

Material: High chromium cast iron

Application: Widely used in metallurgy, electric power, cement, chemical, ceramics, non-metallic minerals, power plant desulfurization, water slag, slag, slag, coal, cement clinker, glass, quartz, limestone and other industries for large-scale material grinding and ultra-fine powder Grinding.

1. High hardness, grinding a variety of materials.

Roller Shell high hardness, Rockwell hardness (HRC) up to 65 degrees, can grind pyrophyllite, calcite, limestone, quartz, gypsum, slag and other materials.

2. Anti-cracking, wear-resistant, overload.

Roller shells adopt high-chromium cast iron grinding material and exquisite metal casting technology. It has good size and crack resistance, good wear resistance and strong load bearing capacity. It has not cracked for 20 years.

3. Factory price sales, cost-effective.

We are a manufacturing factory that sells roller shells directly. There is no middleman to earn the difference, you can save more cost.

4. High-level production.

After the factory has passed 17 professional inspections, the quality inspection system is strictly implemented, and the output is high.

HRM Vertical Roller Mill Roller Shells

| Model | Diameter (mm) |

Height (mm) |

Weight (kg) |

PCS (set) |

Kg (set) |

Hardnedss (HRC) |

|

| HRM080 | Roller Tire | 650 | 210 | 190 | 2-3 | 360-540 | >65 |

| Table Liner | 53 | 6 | 306 | >65 | |||

| HRM1100 | Roller Tire | 900 | 280 | 498 | 2-3 | 960-1440 | >65 |

| Table Liner | 96 | 6 | 558 | >65 | |||

| HRM1200 | Roller Tire | 1000 | 320 | 653 | 2 | 1264 | >65 |

| Table Liner | 105 | 8 | 824 | >65 | |||

| HRM1250 | Roller Tire | 1000 | 320 | 653 | >65 | ||

| Table Liner | 102 | >65 | |||||

| HRM1300 | Roller Tire | 1100(1130) | 360 | 835 | 2 | 1600 | >65 |

| Table Liner | 137 | 8 | 1072 | >65 | |||

| HRM1350 | Roller Tire | 1100 | 360 | 835 | >65 | ||

| Table Liner | 137 | >65 | |||||

| HRM1550 | Roller Tire | 1250 | 420 | 1170 | 3 | >65 | |

| Table Liner | 245 | 8 | >65 | ||||

| HRM1700 | Roller Tire | 1400 | 450 | 1910 | 2 | 3820 | >65 |

| Table Liner | 362 | 6 | 2115 | >65 | |||

| HRM1750 | Roller Tire | 1400 | 470 | 1675 | 3 | >65 | |

| Table Liner | 338 | 8 | >65 | ||||

| HRM1900 | Roller Tire | 1500 | 480 | 2525 | 2 | 4920 | >65 |

| Table Liner | 375 | 8 | 2880 | >65 | |||

| HRM1950 | Roller Tire | 1500 | 480 | 2400 | 3 | >65 | |

| Table Liner | 373 | 8 | >65 | ||||

LM Vertical Roller Mill Roller Shells

| Model | Diameter (mm) |

Height (mm) |

Weight (kg) |

Pcs (set) |

Kg (set) |

Hardnedss (HRC) |

|

| LM110M | Roller Tire | 950 | 320 | 521 | 2 | >65 | |

| Table Liner | 104 | 8 | >65 | ||||

| LUM1232 | Roller Tire | 950 | 310 | 575 | 3 | >65 | |

| Table Liner | 208 | 6 | >65 | ||||

| LM130M | Roller Tire | 1100 | 360 | 768 | 2 | >65 | |

| Table Liner | 133 | 8 | >65 | ||||

| LM130N | Roller Tire | 1100 | 330 | >65 | |||

| Table Liner | >65 | ||||||

| LM150K | Roller Tire | 1300 | 400 | 1360 | >65 | ||

| Table Liner | >65 | ||||||

| LM150K | Roller Tire | 1300 | 400 | 1247 | 2 | >65 | |

| Table Liner | 214 | 8 | >65 | ||||

| LM150N | Roller Tire | 1300 | 370 | 1280 | 2 | >65 | |

| Table Liner | 214 | 8 | >65 | ||||

| LM170K | Roller Tire | 1400 | 450 | 1610 | 2 | >65 | |

| Table Liner | 263 | 8 | >65 | ||||

| LM190M | Roller Tire | 1500 | 480 | 2150 | 2 | >65 | |

| Table Liner | 355 | 8 | >65 | ||||

| LM220K | Roller Tire | 1900 | 650 | 5049 | 2 | >65 | |

| Table Liner | 780 | 9 | >65 | ||||

| LM220M | Roller Tire | 1700 | 560 | 3218 | 2 | >65 | |

| Table Liner | 581 | 8 | >65 | ||||

| LM240M | Roller Tire | >65 | |||||

| Table Liner | 652 | >65 | |||||

ZGM Vertical Roller Mill Roller Shells

| Model | Diameter (mm) |

Height (mm) |

Weight (kg) |

Pcs (set) |

Kg (set) |

Hardnedss (HRC) |

|

| ZGM80G | Roller Tire | 1340 | 445 | >65 | |||

| Table Liner | |||||||

| ZGM80GJ | Roller Tire | 1340 | 445 | 1278/1290 | >65 | ||

| Table Liner | |||||||

| ZGM80K | Roller Tire | >65 | |||||

| Table Liner | |||||||

| ZGM95G | Roller Tire | 1575 | 525 | >65 | |||

| Table Liner | |||||||

| ZGM95GJ | Roller Tire | 1575 | 525 | 1998/1987 | >65 | ||

| Table Liner | |||||||

| ZGM95K | Roller Tire | >65 | |||||

| Table Liner | |||||||

| ZGM95KJ | Roller Tire | >65 | |||||

| Table Liner | |||||||

| ZGM95N | Roller Tire | 1480 | 490 | 1567 | >65 | ||

| Table Liner | |||||||

| ZGM95NJ | Roller Tire | >65 | |||||

| Table Liner | |||||||

| ZGM95KN | Roller Tire | 1480 | 570 | >65 | |||

| Table Liner | |||||||

| ZGM113G | Roller Tire | 1850 | 615 | 3082 | >65 | ||

| Table Liner | |||||||

| ZGM113GJ | Roller Tire | 1850 | 615 | 3340 | >65 | ||

| Table Liner | |||||||

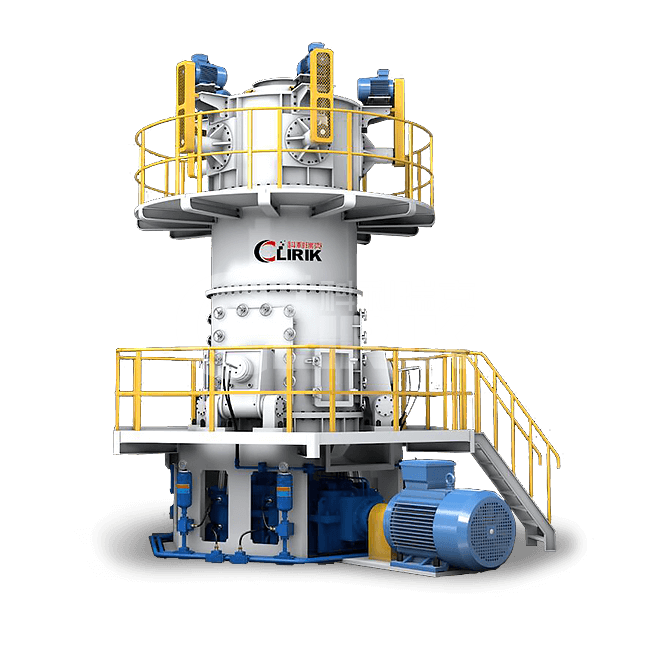

Ultrafine vertical roller mill is a new type of industrial milling equipment that integrates grinding, grading, collecting and conveying. The equipment has the characteristics of large output, high efficiency, low energy consumption, intelligence, environmental protection, etc. It is ideal equipment for the large-scale production of ultrafine powder.

Ultrafine Vertical Roller Mill

Model: CLUM Series

Brand: Clirik

Fineness Size : 400-3000 mesh

Capacity: 3 – 45t/h

Use Range: Gypsum, Calcium Carbonate, Dolomite, Carbon Black, Limestone, Kaolin, Marble…

Application: Mining, Chemiscal, Transport and many other different areas.

Company profile

Shanghai Clirik Machine Co., Ltd. has a professional technical force and perfect production capacity. The company’s products are widely used in mining, road construction, bridge construction, housing construction and other industries, crusher, ultra-fine grinding mill, feeder, vibrating screen, sand washing machine, conveyor and other equipment and series of products, all passed the ISO9001:2000 standard quality certification.

Our Technology

Clirik has more than 12,000 square meters of standardized production plant, including a processing workshop, assembly workshop, painting and sandblasting workshop, trial machine debugging workshop, finished product placement workshop, etc. The workshop is equipped with more than 100 high-end CNC machine tools of well-known foreign brands.

From drawing, assembly to debugging, the equipment manufacturing has gone through thousands of processes, including resizing, cutting, grinding, trimming, heating, forging, turning, milling, grinding and drilling, inspection, painting, assembly and test machine. Each manufacturing process is repeatedly verified by our engineers to ensure the reliability and integrity of each device. Raw materials are related to the quality of products. Our engineers have strict requirements on the selection of raw materials. National standard steel is used.

Other Product

Our equipment will be inspected by QC before leaving the factory. Unqualified products will not be delivered to customers. Clirik Machinery strictly follows ISO 9001: 2008 Quality management system.

Offers various ways of payment, T/T, against copy of B/L, L/C, D/A, D/P, West union, etc.

Normal delivery time within 10 to 20 working days, complete production line or larger equipment may take longer. Exact delivery shall be confirmed when placing the order.

Typically EXW, FOB, CIF, CFR, DAF follows International Rules for the Interpretation of Trade Terms 2010 (INCOTERMS 2010).

We have sea transportation, air transportation, express, land transportation and other modes of transportation.

Customers can choose according to their own needs. We will also give reasonable suggestions to customers considering freight cost, service, shipping date and arrival date.

Clirik has experienced technicians specializing in aftermarket installation services. They will also provide technical training for your operators.

When installation service is needed, the client should pay for technicians’ round way air tickets, salary (shall be confirmed before leaving), food and lodging, most importantly to guarantee the technicians’ safety.