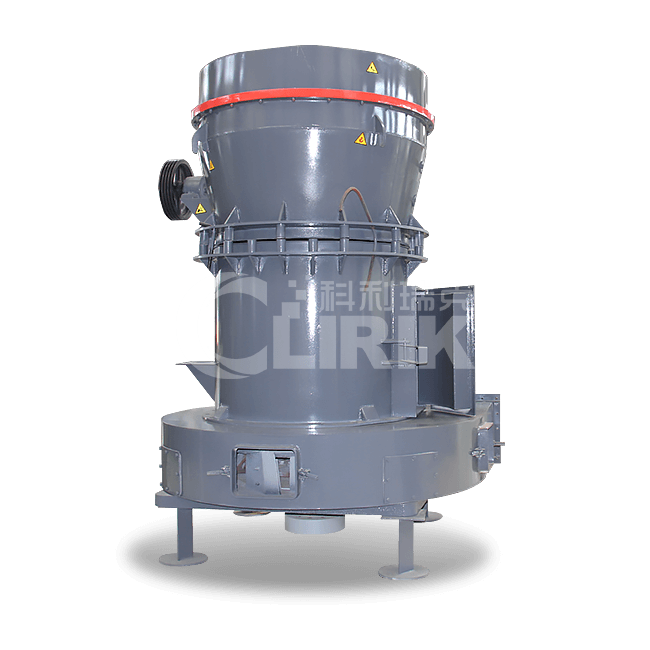

1.High efficiency.

The talc powder raymond mill single machine production capacity is large. Compared with R model grinding mill with the same power, the production increase is 40%.

2.Low noise reduction.

Talc powder raymond mill low operation noise, good energy saving effect, unit power consumption cost savings of 30%, save time, save electricity and save cost.

3.The ideal of environmental protection

Talc powder Raymond roll mill, the patented pulse dust collector, is adopted to achieve 99% high efficiency dust collection. The workshop is clean and tidy, and environmental protection is up to the standard.

4.Easy to maintain

Talc raymond mill new sealing structure design, replacing the grinding ring does not need to remove the roller device, easy maintenance, more convenient.

5.Reliable operation

Talc powder Pulverizer mill the new technologies such as plum frame and longitudinal swing roller mill are fully escorting, making the operation of the equipment more reliable and the performance of the whole machine more reliable.

6.High grading efficiency

Talc powder raymond grinding mill The use of forced turbine classification technology, high classification efficiency, excellent grain shape, greatly enhance the market competitiveness of finished products.