1. High quality powder size.

Talc powder ultrafine vertical roller mill grind fineness of the finished product is D97 5-45 microns. Narrow particle size distribution, can produce 2 micron content of 20%-70% products, greatly improving the added value of finished products and application areas.

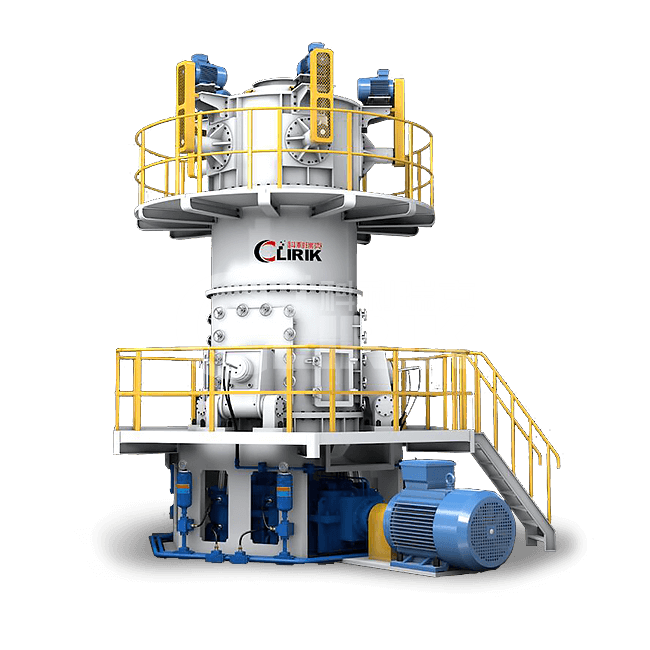

2. Convenient maintenance.

The talc powder ultrafine vertical roller mill grinding wheel and roller plate lining are made of special alloy wear-resistant material, which makes the wearing parts have long service life and low maintenance cost.

3. High efficiency and energy saving

Special grinding structure, forming effective and stable material layer, equipment vibration is small, product pollution-free, good whiteness. Compared with the general mill, the power consumption is 30% less.

4. Environmental Friendly.

The talc powder ultrafine vertical grinding mill roller and grinding disc do not touch each other directly, there does not have the metal impact noise in low vibration. Compared with a ball mill, the running noise is 20-25db lower, which would not hurt a human’s health. Hermetic seal ensures that the system operates under negative pressure. The final powder is conveyed to the final product silo without dust leakage. The environment is clean, meeting the national environmental protection requirements.