What are the advantages of Montmorilonite ultrafine powder grinding mill?

Table of Contents

Advantages of Montmorilonite ultrafine powder grinding mill

Montmorillonite ultrafine powder grinding mills offer several advantages that make them highly valuable for various industrial applications. Here are some of the key advantages:

1. High Efficiency

Enhanced Grinding Efficiency: Montmorillonite ultrafine powder grinding mills are designed to achieve high grinding efficiency, allowing for the rapid processing of montmorillonite into ultrafine powder.

Energy Efficiency: Advanced grinding technologies reduce energy consumption, making the process more cost-effective.

2. Consistent Particle Size

Uniform Output: The mills produce a consistent and uniform particle size, which is crucial for applications requiring precise specifications.

Adjustable Fineness: The fineness of the powder can be easily adjusted to meet specific requirements, ranging from a few microns to sub-micron levels.

3. Advanced Technology

Cutting-Edge Grinding Mechanisms: Utilization of advanced grinding mechanisms such as jet milling, ball milling, or stirred media milling ensures optimal performance.

Innovative Design: Incorporation of state-of-the-art design features enhances the overall efficiency and reliability of the grinding process.

4. Durability and Reliability

Robust Construction: Made from high-quality, wear-resistant materials, these mills are built to handle the abrasive nature of montmorillonite, ensuring a long service life.

Minimal Maintenance: The durable construction reduces the need for frequent maintenance, minimizing downtime and operational costs.

5. Efficient Airflow and Dust Collection

Effective Cooling: An efficient airflow system maintains optimal operating temperatures, preventing overheating and ensuring consistent performance.

Dust Control: Advanced dust collection systems minimize product loss and prevent contamination, ensuring a clean and safe working environment.

6. Versatility

Wide Range of Applications: The ability to produce ultrafine montmorillonite powder makes these mills suitable for various industries, including ceramics, pharmaceuticals, cosmetics, and agriculture.

Adaptability: The Montmorillonite ultrafine powder grinding mills can process different types of montmorillonite and other minerals, offering flexibility in production.

7. Enhanced Product Quality

Improved Functional Properties: Ultrafine montmorillonite powder exhibits enhanced functional properties, such as increased surface area and improved absorption capacity, which are beneficial in numerous applications.

High Purity: Efficient grinding and dust collection systems ensure the final product is of high purity and free from contaminants.

8. Economic Benefits

Cost-Effective Production: High grinding efficiency and reduced energy consumption contribute to lower production costs.

Increased Productivity: The ability to quickly produce large quantities of ultrafine powder boosts overall productivity and profitability.

9. Environmental Impact

Reduced Waste: Efficient dust collection and minimal product loss contribute to a more sustainable production process.

Energy Conservation: Lower energy consumption during the grinding process helps reduce the environmental footprint.

10. User-Friendly Operation

Easy to Operate: The Montmorillonite ultrafine powder grinding mills are designed for ease of use, with intuitive controls and user-friendly interfaces.

Safety Features: Built-in safety features ensure the protection of operators and prevent accidents.

Montmorillonite ultrafine powder grinding mills provide numerous advantages that enhance productivity, product quality, and cost-effectiveness. Their advanced technology, durability, and efficiency make them an essential tool in industries requiring high-quality ultrafine powder.

What is Montmorilonite ultrafine powder grinding mill?

The design and technology of the Montmorillonite ultrafine powder grinding mill enable it to efficiently process various minerals into ultrafine powders. This capability makes the equipment widely applicable across multiple industries, including ceramics, paper, chemicals, construction, and pharmaceuticals. By adjusting the mill’s parameters and configurations, it can meet the processing requirements of different minerals, producing high-quality ultrafine powders that meet specific application needs.

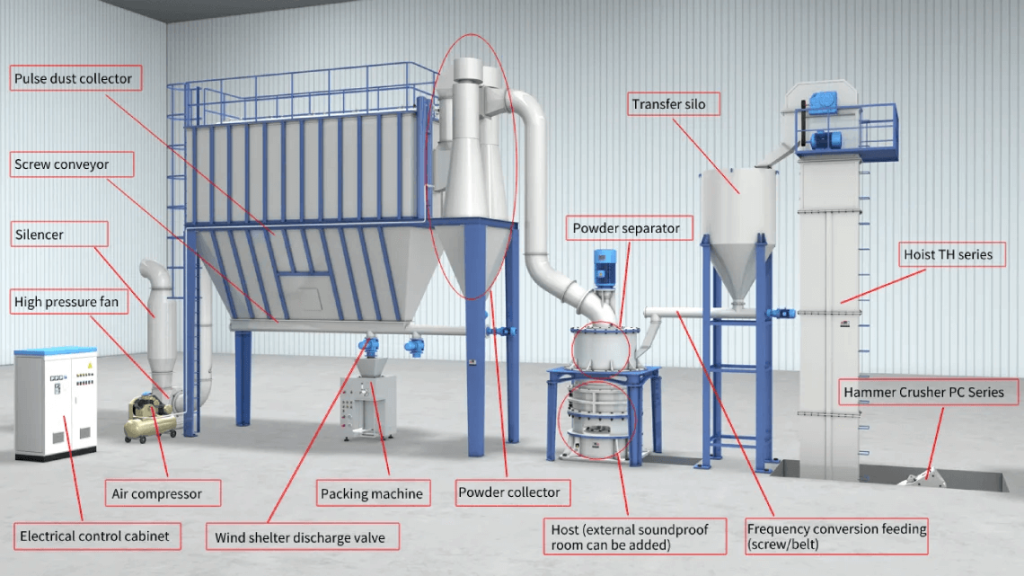

Montmorilonite ultrafine powder grinding mill workflow

1. Raw Material Feeding

Description: The raw montmorillonite material is fed into the grinding mill using a feeder. The material should be dry and, if necessary, pre-crushed to ensure smooth feeding and consistent flow into the mill.

Equipment: Feed hopper, conveyor belt, vibrating feeder.

2. Primary Grinding

Description: The fed material enters the primary grinding chamber, where it undergoes initial size reduction. This stage involves the use of grinding rollers, rings, or other grinding media to crush the material into finer particles.

Equipment: Grinding chamber, grinding rollers, grinding rings, or balls.

3. Secondary Grinding (if applicable)

Description: For achieving ultrafine particle sizes, a secondary grinding stage may be required. This stage further reduces the particle size through additional grinding processes such as jet milling, ball milling, or stirred media milling.

Equipment: Secondary grinding mill (jet mill, ball mill, stirred mill).

4. Classification

Description: The ground material is then passed through a classifier, which separates particles based on size. Fine particles are allowed to pass through, while coarser particles are returned to the grinding chamber for further processing.

Equipment: Classifier, air separator.

5. Collection

Description: The fine, classified particles are collected as the final product. This stage typically involves the use of a cyclone collector or bag filter to capture and collect the ultrafine powder.

Equipment: Cyclone collector, bag filter, dust collector.

6. Cooling and Dust Control

Description: An efficient airflow system is used to cool the grinding chamber and control dust. Proper cooling ensures that the mill operates at optimal temperatures, preventing overheating and maintaining product quality. Dust control systems minimize product loss and prevent contamination.

Equipment: Airflow system, cooling system, dust extraction system.

7. Product Discharge

Description: The collected ultrafine powder is then discharged from the mill and prepared for packaging or further processing, depending on the application requirements.

Equipment: Discharge chute, conveyor belt, packaging equipment.

Workflow Summary

Raw Material Feeding: Feed hopper → Conveyor belt → Vibrating feeder.

Primary Grinding: Grinding chamber with grinding rollers/rings.

Secondary Grinding (if applicable): Secondary grinding mill (jet mill, ball mill, stirred mill).

Classification: Classifier or air separator.

Collection: Cyclone collector or bag filter.

Cooling and Dust Control: Airflow system, cooling system, dust extraction system.

Product Discharge: Discharge chute → Conveyor belt → Packaging equipment.

Advantages of This Workflow

High Efficiency: Multi-stage grinding and classification ensure efficient size reduction and consistent product quality.

Flexibility: Adjustable parameters allow for fine-tuning the process to achieve the desired particle size and distribution.

Dust Control: Advanced dust extraction systems maintain a clean working environment and reduce product loss.

Cooling: Efficient cooling systems prevent overheating, ensuring the mill operates at optimal conditions.

Quality Control: Consistent and uniform particle size is achieved, meeting specific application requirements.

By following this workflow, the Montmorillonite ultrafine powder grinding mill ensures high-quality output, making it suitable for a wide range of industrial applications.

Video presentation of Montmorilonite ultrafine powder grinding mill

-

Previous:What Is Feldspar Powder?

Next:What is barite powder ?