What is a limestone?

Table of Contents

Introduction to limestone

Limestone is a common non-metallic mineral. China is rich in limestone mineral resources, accounting for more than 64% of the world’s total reserves. It is a natural resource with advantages.

The main component of limestone is calcium carbonate (CaCO3). It is a kind of inorganic compound, commonly known as limestone, limestone, stone powder, marble, etc.

Calcium carbonate is neutral, basically insoluble in water, soluble in hydrochloric acid. It is one of the common substances on earth. It exists in aragonite, calcite, chalk, limestone, marble, travertine and other rocks. It is also the main component of animal bones or shells.

Application of limestone

1.Foundry sand for manufacturing machinery .

The casting sand produced by limestone has a particle size of 28 ~ 75 mesh, which has better performance than quartz sand, good collapsibility, easy sand cleaning, improves the surface quality of castings, increases the surface finish of castings, and basically eliminates the harm of silicates to workers. According to statistics, there are tens of thousands of tons of casting sand purchased by large iron and steel enterprises alone, which is a potential market for the limestone metallurgy industry.

2.Used in industrial building materials coating and other industries.

Limestone powder grinding to 100-200 mesh, can be directly used to produce Shuangfei powder, putty powder and other industrial building materials powder; in mixing stations, highway construction is also the main raw material. Limestone powder coating can improve the thxotropy of the system, can significantly improve the adhesion, brush resistance, stain resistance of the coating, improve the strength and surface finish, and has a good anti-settling effect. Partial replacement of titanium dioxide reduces the cost.

3.Production of desulfurization absorbent.

The limestone powder is ground to 200-325 mesh to replace the original lime or lime, and water is mixed into the absorption tower to stir the slurry, and the slurry is mixed with the flue gas. The sulfur dioxide in the flue gas and the calcium carbonate and air in the slurry enter the chemical reaction and are removed, and the final reaction product is gypsum. The decelerated flu gas is heated and placed in the chimney. Mature process equipment, high desulfurization efficiency, a wide range of applications.

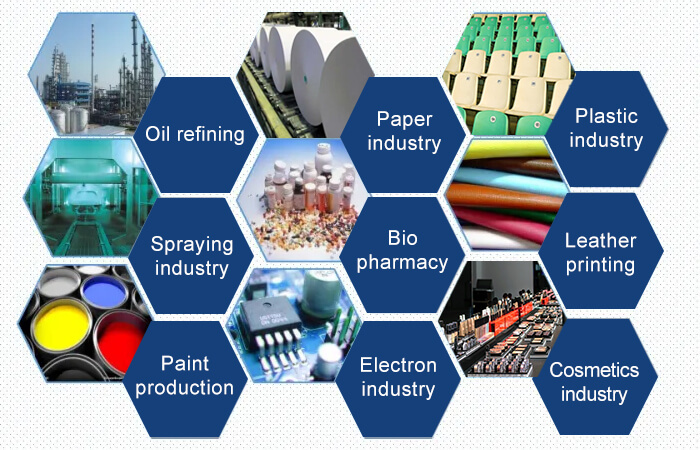

4.As filler in plastic, coating and other production processes.

The product is made of natural calcium carbonate minerals as raw materials, namely limestone, should contain CaCO3(dry base): excellent 9810%, first-class 9610%, second-class 9410%, Fe2O3≤011%, Mn≤0102%, Cu≤ 01001%, whiteness of more than 90. In addition, the general average particle size of 400-800 purpose powder used as coating filler, 800-1250 mesh used as plastic, rubber, paper filler, 2500 mesh activated treatment used as ink filler.

5.Limestone can be used in industry to make glass.

The main materials of glass are quartz stone, soda ash, limestone, etc., and these materials are melted in a high temperature environment. Limestone can also be used to make steel. The lime in limestone can be used in industry as a slagging material to filter out sulfur, phosphorus and other substances in the steelmaking process.

6.Limeston can be used in food processing.

Limestone can be transformed into calcium salts such as calcium sulfite, calcium nitrate and calcium chloride after many chemical reactions. Hydrated lime can also temporarily remove hardness from water, especially as a hard water softener in industry.

7. Limeston can be used in agriculture.

Limestone is also widely used in agriculture. Limestone can be configured into lime sulfur mixture, Bordeaux liquid and other pesticides. In addition, the use of hydrated lime can also change the acid and alkaline of the soil, make the soil properties change, improve the internal structure of the soil, and replenish the calcium in the soil. In addition, the tree trunk can be painted with stone plaster, which is used to protect the tree.

Limestone processing machine

Limestone is widely used and the product market is promising.

The processing of limestone mainly includes crushing, grading and production of lime, hydrated lime, precipitated calcium carbonate, carbon dioxide and so on. Limestone is generally pulverized by a dry crushing process.Based on the development status of deep processing of limestone products at home and abroad, several kinds of commonly used limestone processing machinery are introduced.

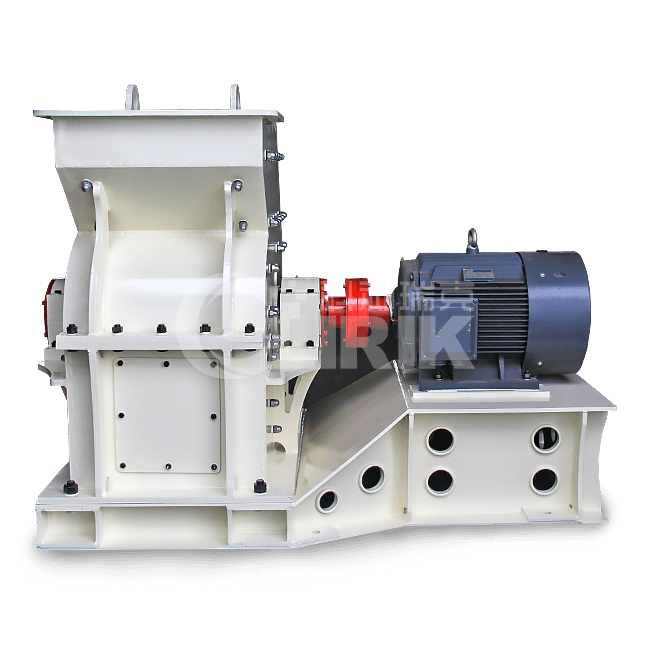

Limestone Powder Hammer Crusher

Processing ability: 5-30 t/h

Fineness: 0-25 mm

Max feeding size: <350 mm

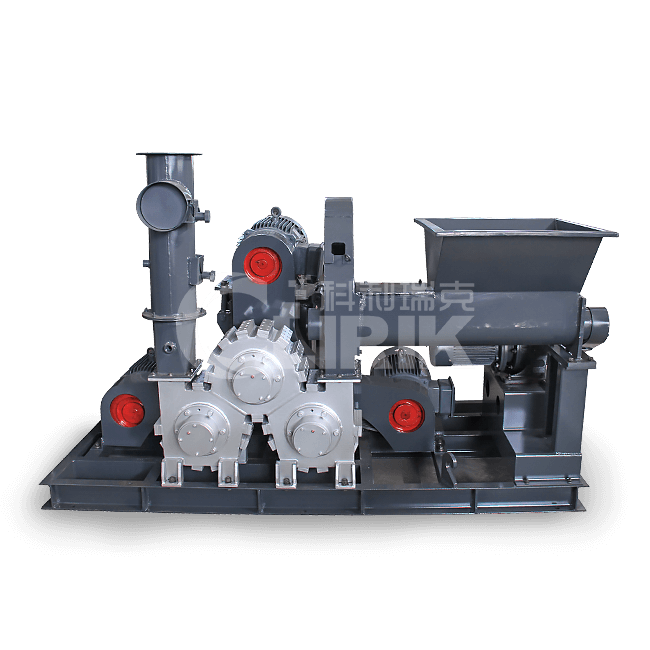

Limestone Powder Suface Coating Machine

Processing ability: 40-7000 kg/h

Change the properties of limestone powder and expand the application field of limestone powder.

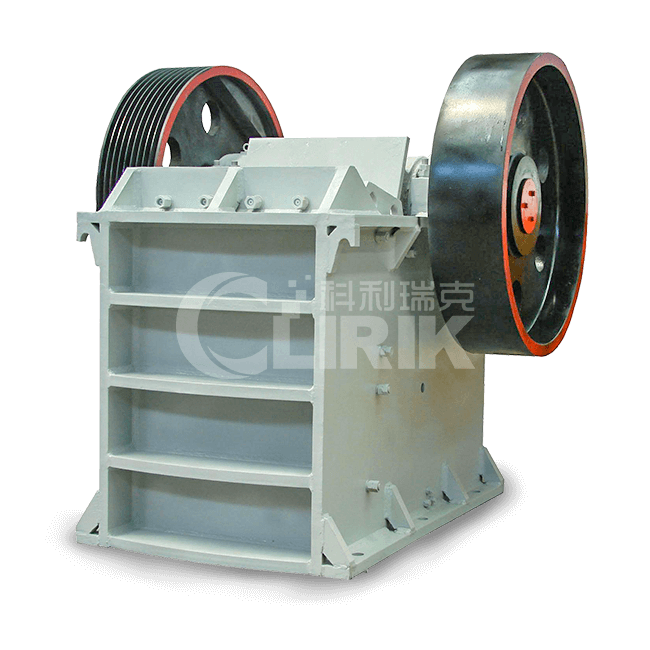

Limestone Powder Jaw Crusher

Processing ability: 1-40 t/h

Fineness: 10-265 mm

Max feeding size: 125-850 mm

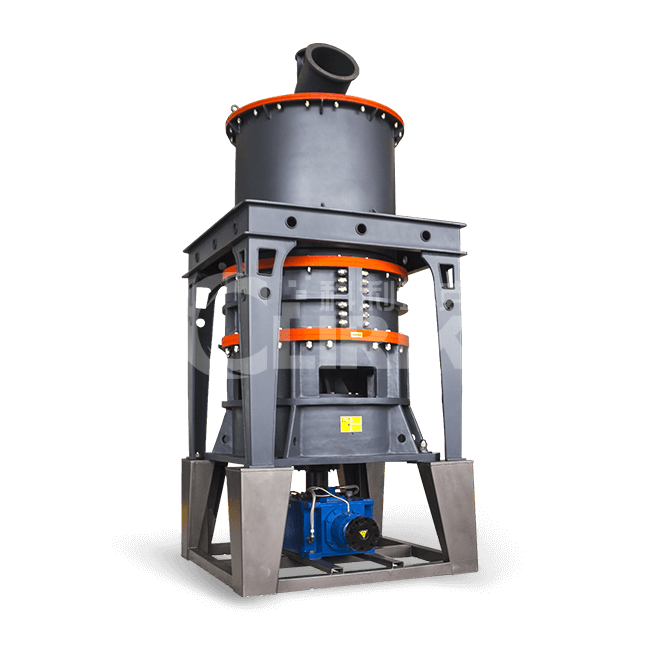

Limestone Powder Ultrafine Vertical Powder Grinding Mill

Processing ability: 1-20t/h

Fineness: 400-3000

Max feeding size: 10mm

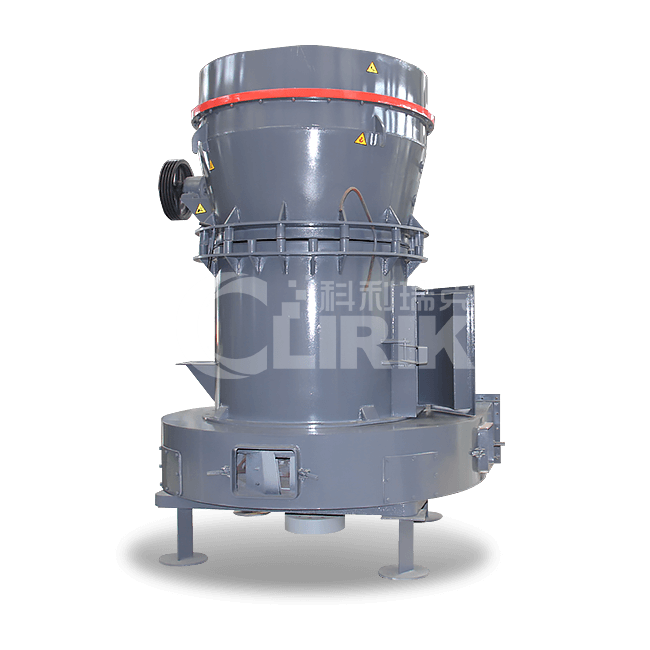

Limestone Powder Ultrafine Powder Grinding Mill

Processing ability: 1-45 t/h

Fineness: 150-3000 mesh

Max feeding size: 10-25mm

Limestone Powder High Pressure Suspension Grinding Mill

Processing ability: 1-30t/h

Fineness: 50-325 mesh

Max feeding size: 20mm

-

Previous:What’s the gypsum powder?

Next:What is the talc powder?