What is barite powder ?

Table of Contents

Introduction of Barite powder

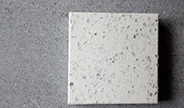

Barite powder is a fine powder made from barite, a mineral composed of barium sulfate (BaSO₄). Barite is naturally occurring and is known for its high density, chemical inertness, and ability to absorb X-rays and gamma rays. These properties make barite powder valuable in various industrial applications, including:

1. Oil and Gas Drilling: Barite powder is widely used as a weighting agent in drilling fluids, which helps to control the pressure in the wellbore during drilling operations. The high density of barite helps to prevent blowouts and ensure the stability of the borehole.

2. Paints and Coatings: In the paint industry, barite powder is used as a filler to enhance the density and improve the brightness and smoothness of the finished product.

3. Plastics: Barite powder is used as a filler in the production of plastics to increase the weight and improve the physical properties of the final product.

4. Rubber: It is also used in the rubber industry as a filler and to enhance the strength and durability of rubber products.

5. Pharmaceuticals: In the medical field, barite powder is used in barium meals or barium swallows for radiographic imaging of the digestive system. It helps to visualize the digestive tract in X-rays by providing contrast.

6. Chemical Industry: Barite powder is used in the production of barium compounds, which are used in various chemical processes.

7. Construction: In construction, barite powder is used as an aggregate in heavy concrete for shielding against radiation in nuclear facilities.

The powder is produced by crushing and grinding barite ore, typically using grinding mills, and then refining it to the desired particle size.

What is barite?

Barite, also known as baryte, is a mineral composed of barium sulfate (BaSO₄). It is typically white or colorless, but can also appear in various shades such as light blue, yellow, or brown due to impurities. Barite is a dense mineral, with a high specific gravity, which makes it useful in a variety of industrial applications.

Key Characteristics

Chemical Formula: BaSO₄

Color: White, colorless, or various shades depending on impurities

Density: High (about 4.5 g/cm³)

Hardness: 3 to 3.5 on the Mohs scale

Barite is found in various geological environments, including sedimentary rocks, hydrothermal veins, and as a byproduct of volcanic activity.

How to process barite into powder?

Processing barite into powder involves several steps to reduce the mineral to a fine, uniform size suitable for various industrial applications. The process typically includes crushing, grinding, classification, and sometimes further refinement. Below is an overview of the process:

1. Crushing

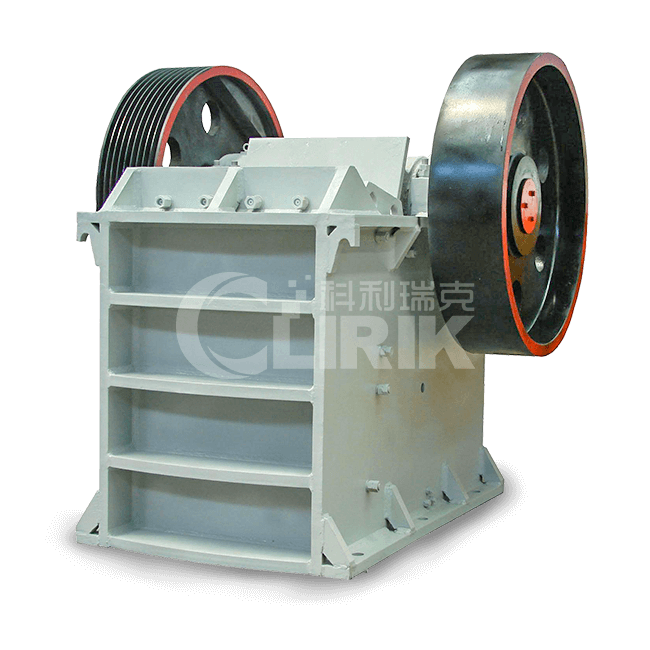

Primary Crushing: Large pieces of barite are fed into a jaw crusher or impact crusher to reduce them to smaller sizes, typically around 2-3 inches in diameter.

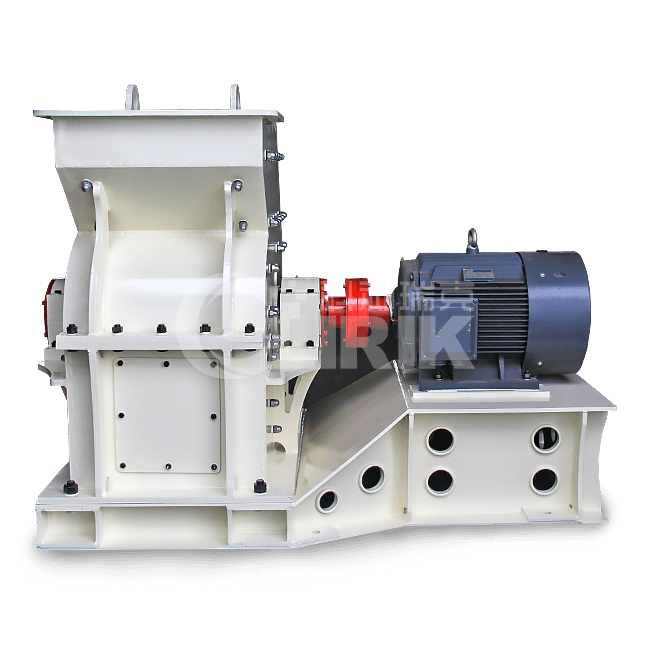

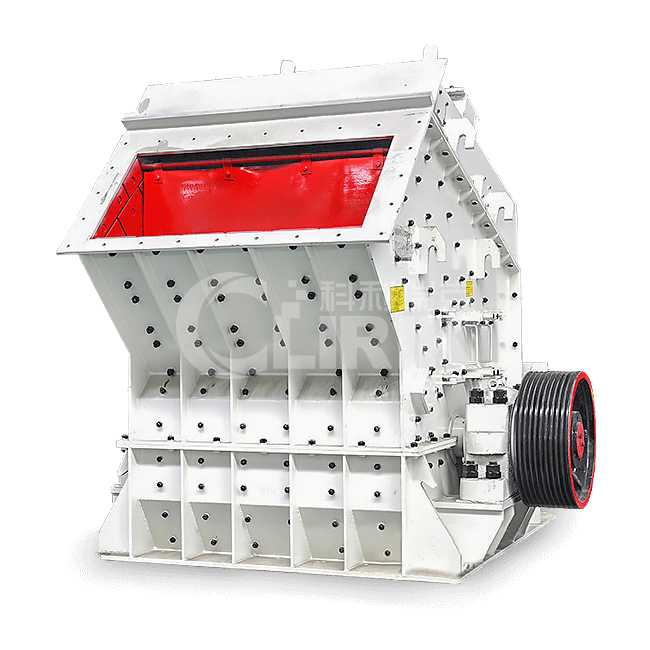

Secondary Crushing: The crushed barite is further reduced using a cone crusher or impact crusher to achieve a more uniform size, usually less than 1 inch.

2. Grinding

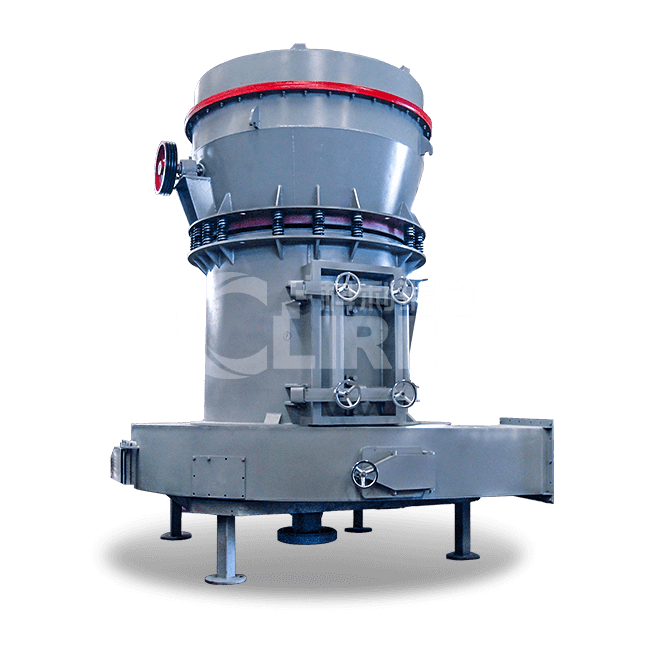

Ball Mill or Raymond Mill: The crushed barite is fed into a grinding mill, such as a ball mill or Raymond mill, where it is ground into a fine powder. The particle size can be controlled by adjusting the grinding time, speed, and the type of grinding media used.

Ultrafine Grinding: For applications requiring a finer powder, an HGM ultrafine grinding mill or similar equipment can be used to achieve particle sizes as fine as 5-45 microns. This is especially important in applications like high-density fillers or barium chemicals.

3. Classification

Air Classifier: The ground barite powder is then passed through an air classifier, which separates particles based on size. Larger particles are returned to the grinding mill for further processing, while finer particles are collected for use.

Sieving: Alternatively, the powder can be passed through sieves with different mesh sizes to achieve the desired particle size distribution.

4. Optional Processing

Surface Modification: In some cases, the barite powder may undergo surface treatment to improve its compatibility with other materials in specific applications, such as in plastics or rubber.

Purification: If the barite contains impurities, additional processing steps like flotation or magnetic separation may be used to purify the final product.

5. Packaging

The final barite powder is then packaged in bags or bulk containers for shipment to customers. The packaging process ensures that the powder remains dry and free from contamination.

Key Equipment Used

Crushers: Jaw crusher, impact crusher, cone crusher.

Grinding Mills: Ball mill, Raymond mill, HGM ultrafine grinding mill.

Classifiers: Air classifiers, sieves.

Surface Treatment Equipment: If required for specific applications.