What is Bauxite Powder?

Table of Contents

Introduction of Bauxite

Bauxite is a naturally occurring, heterogeneous material composed primarily of aluminum hydroxide minerals, along with various impurities such as iron oxide, silica, and titania. It is the primary ore of aluminum and is typically found in tropical or subtropical regions.

Composition: Bauxite primarily consists of aluminum hydroxide minerals, including gibbsite, boehmite, and diaspore. These minerals are usually mixed with varying amounts of impurities such as iron oxide (Fe2O3), silica (SiO2), and titania (TiO2).

Appearance: Bauxite can vary in color from reddish-brown to white, depending on the composition and impurities present. It often has a pisolitic or nodular structure due to the concentration of aluminum hydroxide minerals.

Formation: Bauxite forms through weathering and chemical decomposition of aluminum-rich rocks under tropical or subtropical conditions. The process typically involves the leaching of aluminum from parent rocks and subsequent concentration in residual soils or sedimentary deposits.

Mining and Extraction: Bauxite is mined through open-pit or strip mining methods. After extraction, the ore undergoes beneficiation to remove impurities and improve its aluminum content. The primary method of aluminum extraction from bauxite is the Bayer process, which involves digestion of the ore with caustic soda (sodium hydroxide) at elevated temperatures to dissolve the aluminum hydroxide minerals. The resulting solution is then processed to extract pure aluminum hydroxide, which can be further refined into aluminum metal through electrolysis.

Uses: The primary use of bauxite is as a raw material for the production of aluminum metal. Aluminum is widely used in various industries, including aerospace, automotive, construction, packaging, and electronics, due to its lightweight, corrosion resistance, and excellent conductivity properties. Additionally, bauxite-derived alumina (aluminum oxide) is used in the manufacture of abrasives, refractories, ceramics, and other industrial applications.

Introduction of Bauxite Powder

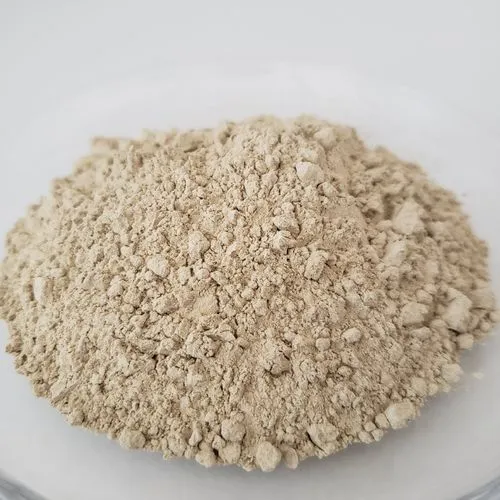

Bauxite powder refers to finely ground bauxite ore that has been processed into a fine powder form. It is typically produced by crushing and grinding raw bauxite ore into a fine particle size to facilitate its use in various applications.

Production: Bauxite powder is produced through the process of grinding raw bauxite ore into a fine powder form. This process involves crushing the bauxite ore into smaller particles and then grinding it into a fine powder using grinding mills or pulverizers.

Particle Size: The particle size of bauxite powder can vary depending on the specific requirements of its intended use. It can range from coarse particles to very fine powders, typically with particle sizes ranging from a few micrometers to several tens of micrometers.

Composition: Bauxite powder retains the chemical composition of the original bauxite ore, primarily consisting of aluminum hydroxide minerals (such as gibbsite, boehmite, and diaspore) along with various impurities such as iron oxide, silica, and titania.

Uses: Bauxite powder has various industrial applications due to its aluminum content and other properties. Some common uses include:

- 1. Refractory applications: Bauxite powder is used as a raw material in the production of refractory bricks, castables, and other refractory products due to its high aluminum content and heat-resistant properties.

- 2. Abrasives: Bauxite powder is used as an abrasive material in the manufacturing of abrasives such as grinding wheels, sandpaper, and polishing compounds.

- 3. Welding fluxes: Bauxite powder is sometimes used as a fluxing agent in welding applications to help remove impurities and improve the weld quality.

- 4. Filler material: Bauxite powder can be used as a filler material in various industries such as plastics, rubber, and ceramics to enhance product properties and reduce costs.

Bauxite powder processing machine

Bauxite is a common ore used in the production of aluminum, and grinding it into a fine powder can be necessary for various industrial applications. Ultrafine grinding mills are designed to produce extremely fine powders, often in the micron or sub-micron range, suitable for applications where a high degree of fineness is required.

There are several types of ultrafine grinding mills that can be used for bauxite powder processing:

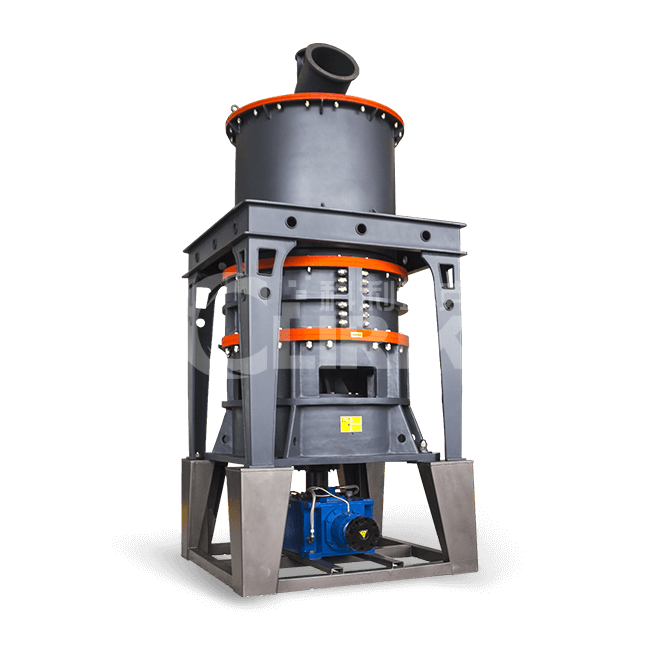

1. Ultrafine Grinding Mill: HGM series ultrafine powder grinding mills often incorporate advanced technology such as high-speed rotation, air classification, or other mechanisms to achieve ultrafine particle sizes.

2. Ball Mill: While not typically considered an ultrafine grinding mill, ball mills can achieve ultrafine particle sizes by using balls of very small size within the mill. They are commonly used in the mining industry for fine grinding of ores, including bauxite.

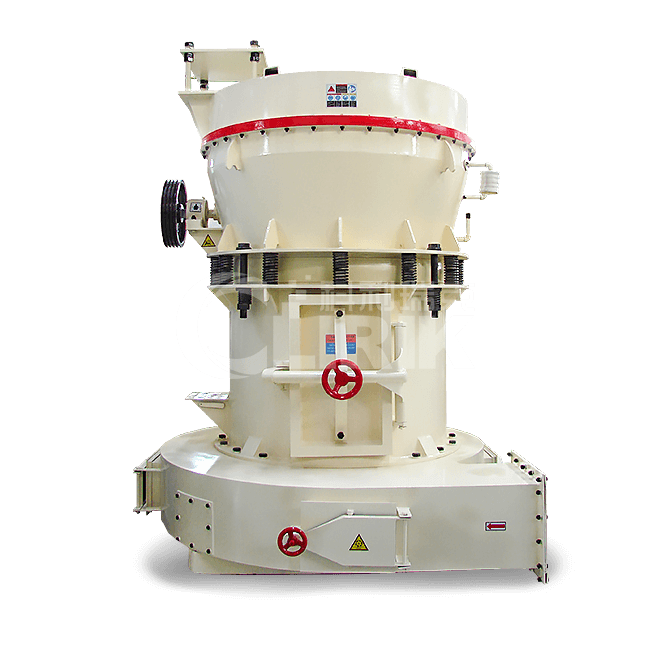

3. Vertical Roller Mill (CLUM): CLUM series vertical roller mill technology allows grinding of materials in a much narrower particle size distribution than traditional ball mills. This can be beneficial for achieving ultrafine particles in bauxite grinding.

4. Enhanced Roller Grinding Mill: CLRM series enhanced roller grinding mill is suitable for processing various non-flammable and non-explosive mineral materials with Moh’s hardness less than 6 and humidity less than 6%. The particle size of the finished aluminum ore powder can be adjusted between 80-500 mesh (180-30 microns).

When selecting an ultrafine grinding mill for bauxite powder processing, factors such as desired particle size, production capacity, energy consumption, and cost should be considered. It’s also important to ensure that the chosen mill is capable of handling the specific characteristics of bauxite ore, such as its hardness and abrasiveness. Additionally, proper maintenance and operational considerations should be taken into account to ensure efficient and reliable operation of the grinding mill.