What is carbon black ?

Table of Contents

What is carbon black ?

Carbon black is a kind of amorphous carbon, which is a light, loose and extremely fine black powder with a very large surface area ranging from 10 to 3000m2/g. It is a carbonaceous substance (coal, natural gas, heavy oil, fuel oil, etc.) are the products obtained by incomplete combustion or thermal decomposition under the condition of insufficient air.

The one made from natural gas is called “gas black”, the one made from oil is called “lamp black”, and the one made from acetylene is called “acetylene black”. In addition, there are “slot black” and “furnace black”. According to the performance of carbon black, there are “reinforcing carbon black”, “conductive carbon black”, “wear-resistant carbon black” and so on. It can be used as a black dye, used in the manufacture of Chinese ink, printing ink, paint, etc., and also used as a reinforcing agent for rubber.

Classification of carbon black

Classified by production

Mainly divided into lamp black, gas black, furnace black and slot black.

Classification by purpose

According to different uses, carbon black is usually divided into carbon black for pigments, carbon black for rubber, conductive carbon black and special carbon black.

Carbon black for pigments—Internationally, according to the coloring ability of carbon black, it is usually divided into three categories, namely high-pigment carbon black, medium-pigment carbon black and low-pigment carbon black. This classification is usually represented by three English letters, The first two letters indicate the coloring ability of carbon black, and the last letter indicates the production method.

Carbon black for rubber – Carbon black for rubber was originally classified by particle size, but was later classified by nitrogen surface area.

In addition, factors such as the vulcanization speed and structure of carbon black pigments are also taken into account when naming, and it consists of 4 systems. The first English letter represents the vulcanization speed of the rubber compound, with N representing the normal vulcanization speed and S representing the slow vulcanization speed. The last three are Arabic numerals. The first number represents the range of carbon black nitrogen surface area, which is listed as 0~9 grades. The second and third numbers are specified by the D24.41 Committee of the American Society for Testing and Materials responsible for carbon black and terminology, reflecting different structural degrees, that is, the approximate high and low structure of carbon black, which has a certain degree of arbitrariness. Relatively speaking, the larger the number, the taller the structure.

Classified by function

Mainly divided into reinforcing carbon black, colored carbon black, conductive carbon black and so on.

Classified by model

Mainly divided into N220, N330, N550, N660, N990, N110, N115, N234, N326, N339, N375, N539, N550, N880, etc.

What fields can carbon black be used in?

Black carbon can be used in tires, plastics, food contact grades, batteries, high performance coatings, rubber goods, pipe, agricultural irrigation, mulch films and greenhouse coverings, automotive skin contact, wire and cable, toner and printing Inks.

Tires

Carbon black is used to improve the processing, strength and durability important to tire manufacturing and tire performance (most notably safety), increasing tire life and fuel economy.

Automotive Skin Contact

Low PAH carbon black provide excellent UV protection for internal automotive components designed to come into contact with skin (steering wheel, gear shift, arm rests, etc.)

Plastics

Carbon black provides color, UV protection and conductivity – power cable shielding or electrostatic dissipation – to plastics

Batteries

Carbon black improves electrochemical conductivity and charging characteristics in lead-acid, modern stop-start, and hybrid batteries – improving overall battery efficiency.

Wire and Cable

Carbon black extends cable life and efficiency by creating exceptionally smooth and conductive insulation, conductor shield and UV resistance.

Food Contact Grades

Specific carbon black grades comply with stringent purity requirements for many regulated industrial or consumer plastic applications.

How is Carbon Black powder Produced?

Black carbon production process

It is made of hydrocarbon compounds (mainly petroleum derivatives), through the incomplete combustion or pyrolysis of hydrocarbons at high temperature, but the hydrogen and oxygen elements in it are converted into water, and the carbon element combustion is not enough, will be separated from the molecules, the formation of carbon black.

Black carbon powder production process

Put the carbon black into the carbon black mill for grinding into powder.

Carbon black powder production machine

HGM Series Ultrafine Powder Grinding Mill

Finished Size: 150-2500 mesh

Processing Ability: 1-45 t/h

Max Feeding Size: 10-25 mm

MQQ : 1 Set

Price: 59999- 159999 $

Range Of Application: Black carbon, Calcium Carbonate, Limestone, Kaolin, Gypsum, Bentonite, Dolomite…

CLUM Series Ultrafine Vertical Roller Mill

Finished Size : 600~3000 mesh

Processing Ability : 3 – 45t/h

Max feeding Size : 10 mm

MQQ : 1 Set

Price: 129999-599999 $

Range Of Application: Calcium Carbonate, Limestone, Kaolin, Gypsum, Bentonite, Dolomite…

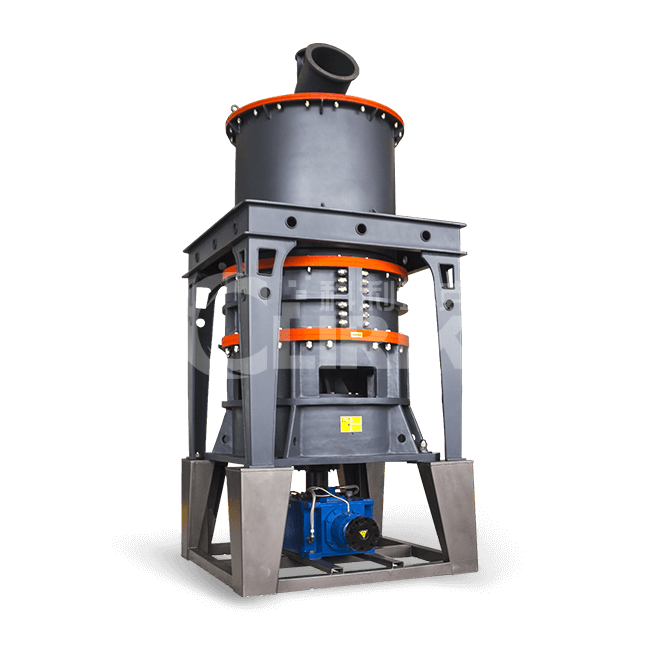

CLRM series enhanced roller grinding mill

Finished Size: 80-300 mesh

MQQ: 1 Set

Price: 19999-69999 $

Capacity: 1-35 t/h

Max feeding size: 35 mm

Range of application: Calcium carbonate, quartz, feldspar, barite, calcite carbonate, Black carbon, limestone, talc, ceramic,iron ore, carborundum, bauxite, rock phosphate, coal…

Carbon black powder production video

-

Previous:Grinding mill equipment delivery is busy

Next:Clirik start working