What Is Feldspar Powder?

Table of Contents

Brief Introduction of Feldspar Powder

Feldspar powder is a key raw material used in various industrial applications, primarily due to its alumina and silica content.

Properties of Feldspar Powder

Chemical Composition: Feldspar is primarily composed of aluminum silicates along with potassium, sodium, and calcium.

Physical Properties: Hardness: 6-6.5 on the Mohs scale.

Density: Typically around 2.56-2.76 g/cm³.

Melting Point: Varies between 1100°C to 1550°C depending on the type.

Appearance: It is usually white or nearly white but can have shades of pink, brown, or grey due to impurities.

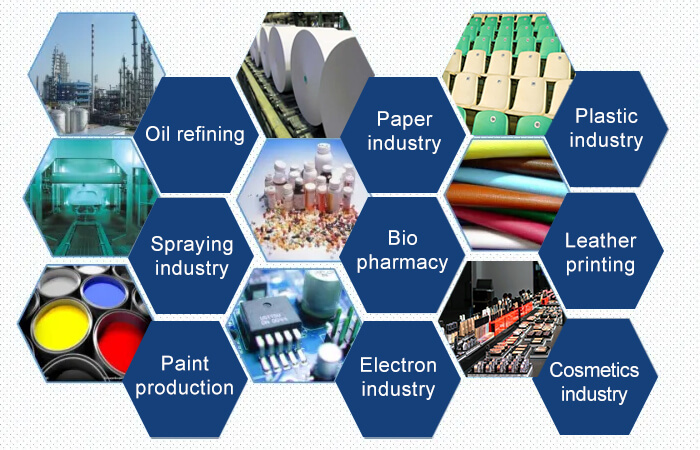

Uses of Feldspar Powder

Glass Industry: Feldspar provides alumina content which improves hardness, durability, and resistance to chemical corrosion in glass products.

Ceramics: Acts as a fluxing agent to form a glassy phase at low temperatures and provides strength and durability to ceramic bodies.

Fillers: Used as fillers in paint, plastics, rubber, and adhesive products due to its stable chemical properties and non-reactive nature.

Abrasives: Due to its hardness, feldspar is used as an abrasive material in scouring powders, sandpapers, and other applications.

Fluxing Agent: In the manufacture of welding rods, feldspar acts as a fluxing agent.

What Is Feldspar?

Feldspar is a group of rock-forming minerals that make up about 60% of the Earth’s crust. These minerals are highly significant in both geology and industrial applications due to their abundance and varied properties.

Types of Feldspar

Potassium Feldspar (K-spar): Rich in potassium, it is often used in ceramics and glass industries.

Sodium Feldspar (Albite): Rich in sodium, it is typically used in ceramics, glass, and enamel industries.

Calcium Feldspar (Anorthite): Rich in calcium, used in the manufacture of ceramics and some glass products.

Manufacturing and Processing

Mining: Feldspar is extracted from open-pit mines.

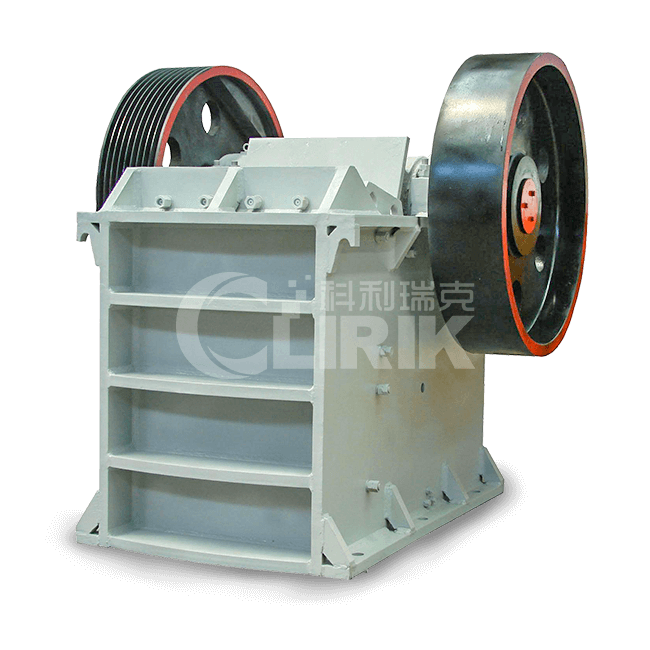

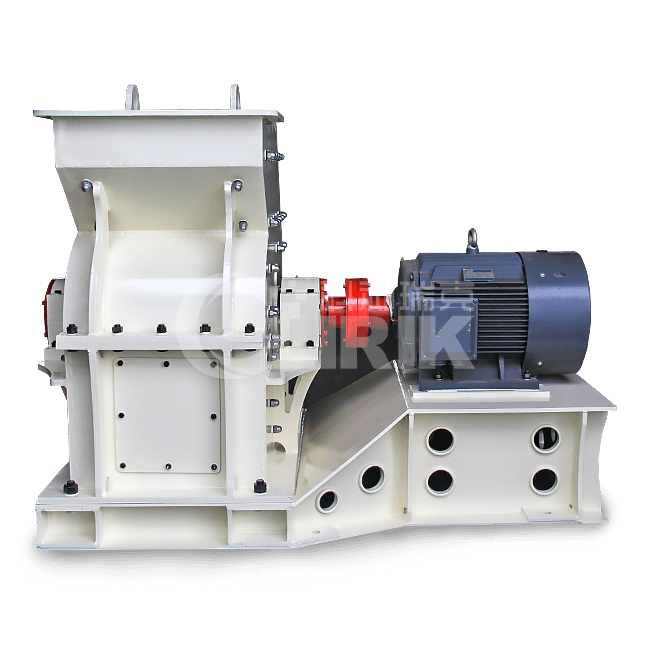

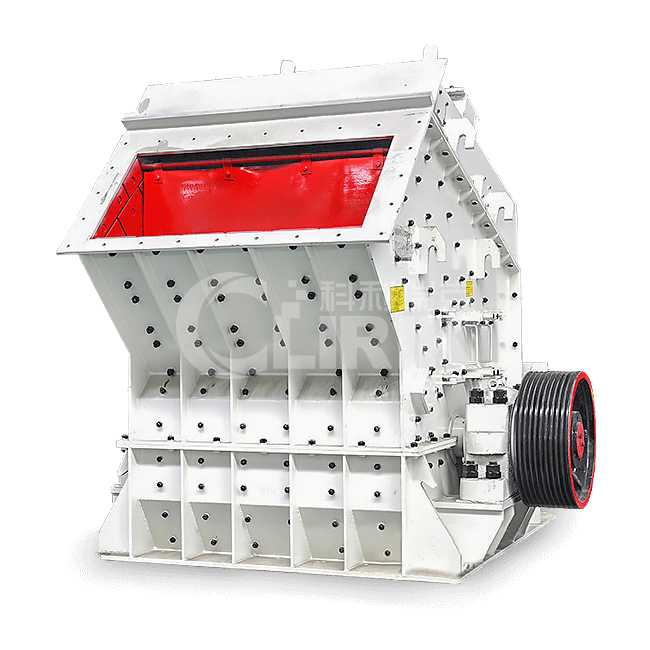

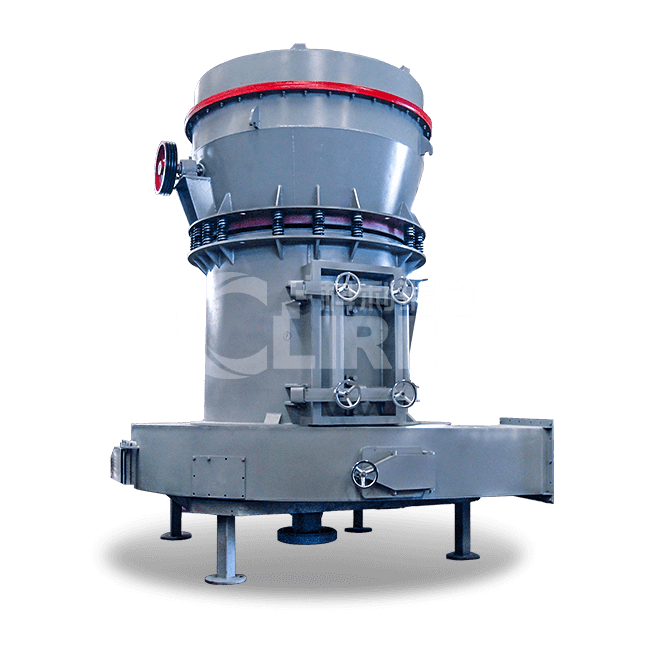

Crushing and Grinding: The raw material( Feldspar) is crushed and ground into a fine powder.

Purification: Magnetic separation and flotation processes are used to remove impurities like iron and mica.