What is Montmorillonite?

Table of Contents

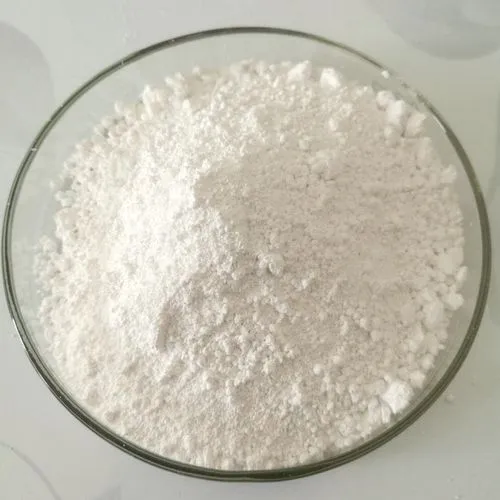

Introduction Of Montmorillonite

Montmorillonite is a type of clay mineral that belongs to the smectite group. It is known for its unique properties, including high cation-exchange capacity, swelling ability, and high surface area. Here are some key points about montmorillonite:

Composition

Montmorillonite is a hydrated sodium calcium aluminum magnesium silicate hydroxide. Its general chemical formula is (𝑁𝑎,𝐶𝑎)0.33(𝐴𝑙,𝑀𝑔)2(𝑆𝑖4𝑂10)(𝑂𝐻)2⋅𝑛𝐻2𝑂(Na,Ca)0.33(Al,Mg)2(Si4O10)(OH)2⋅nH2O.

Structure

It has a layered structure, with layers of silicon-oxygen tetrahedra (silica sheets) and aluminum-oxygen-hydroxyl octahedra (alumina sheets). These layers are held together by weak van der Waals forces, allowing water and other molecules to intercalate between them, leading to swelling.

Properties

1. Swelling: Montmorillonite can absorb water and swell, sometimes increasing its volume several times.

2. Cation-Exchange Capacity (CEC): It can exchange cations (positively charged ions) within its structure with cations in a solution, making it useful in various chemical processes.

3. Adsorption: Its large surface area and ability to adsorb molecules make it effective in purification and detoxification processes.

Advantages of Montmorillonite powder

Montmorillonite powder, due to its unique physical and chemical properties, has a wide range of applications in many fields and offers numerous advantages. Here are some of the main benefits of Montmorillonite powder:

High Adsorption Capacity

1. Water Absorption: Montmorillonite powder has a strong ability to absorb water, significantly swelling and increasing in volume.

2. Pollutant Adsorption: It can effectively adsorb heavy metals, toxins, chemicals, and other pollutants.

High Cation Exchange Capacity (CEC):

Montmorillonite powder can exchange and fix cations, which is very useful for improving soil structure and enhancing soil fertility.

Thickening and Suspension Properties

It can form stable suspensions in water, making it an excellent thickening and suspending agent.

Environmental Friendliness and Safety

As a natural material, it is safe, non-toxic, and biodegradable.

Good Dispersibility

It disperses well in various media, important for preparing uniform mixtures.

High Surface Area and Porosity:

The high surface area and porous structure give it significant advantages in adsorbing gases, liquids, and solutes.

Chemical Stability

It exhibits good stability in various chemical environments.

Application of Montmorillonite powder

Industrial Applications

1. Drilling Mud: Used as a primary component in drilling muds due to its thickening and stabilizing properties.

2. Foundry Sand Binder: Acts as a binder in foundry sand, improving the quality of castings.

Adsorbent and Catalyst Carrier: Used as an adsorbent and catalyst carrier in chemical and environmental engineering.

Environmental Protection

1. Pollutant Treatment: Used for the removal of heavy metals and organic pollutants from water and soil.

2. Landfill Barriers: Used as a bottom barrier in landfills to prevent the permeation of harmful substances.

Agricultural Applications

1. Soil Conditioner: Improves soil structure, enhancing water retention and nutrient-holding capacity.

2. Feed Additive: Used in animal husbandry to adsorb mycotoxins in feed, protecting animal health.

Pharmaceuticals and Cosmetics

1. Drug Carrier: Acts as a drug carrier, enhancing the stability and absorption of medications.

2. Skincare Products: Used in masks and cleansers to adsorb oils and impurities from the skin.

Daily Use Products

1. Cat Litter: Its high water absorption and deodorizing properties make it an ideal material for cat litter.

Food Packaging: Used in food preservatives and humidity control.

2. Food Packaging: Used in food preservatives and humidity control.

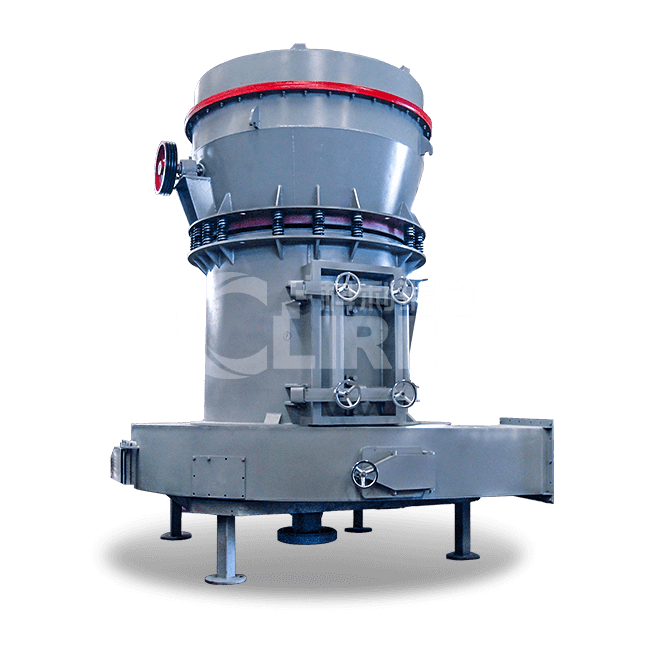

Machines for Processing Montmorillonite Powder

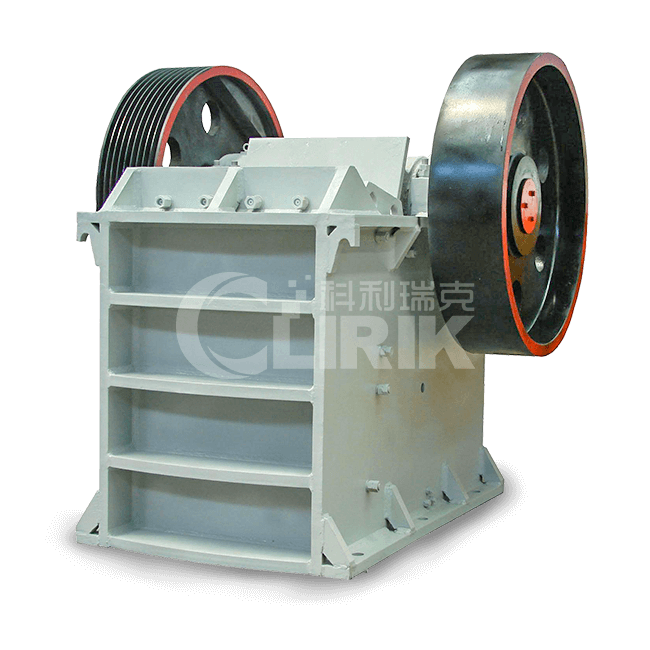

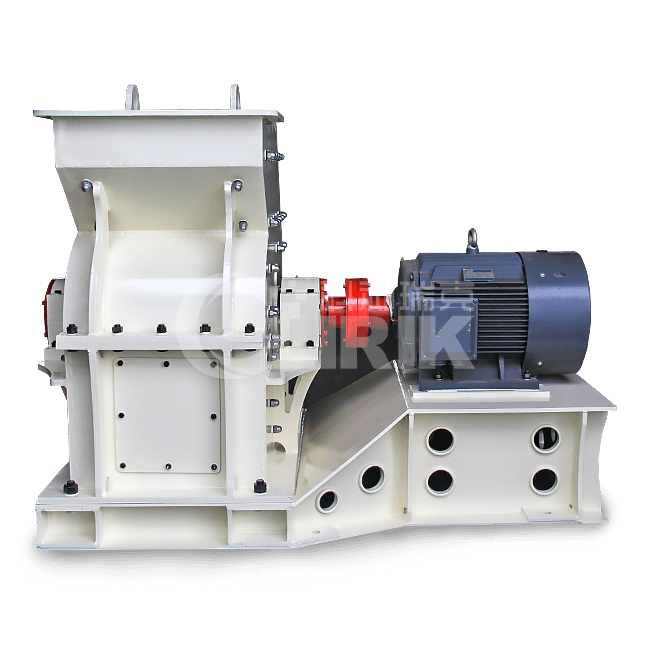

Crushing Equipment

1. Jaw Crusher: Used for the initial crushing of raw montmorillonite into smaller pieces.

2. Impact Crusher: Further reduces the size of the montmorillonite particles.

Grinding Equipment

1. YGM Series Raymond Grinding Mill:Used to grind montmorillonite into fine powder with a particle size of 50-325 mesh.

2. CLRM Series Enhanced Roller Grinding Mill:Used to grind montmorillonite into fine powder with a particle size of 80-500 mesh.

3. HGM Series Micro Powder Grinding Mill: Used to grind montmorillonite into fine powder with a particle size of 150-2500 mesh.

4. CLUM series ultrafine vertical roller mill: Used to grind montmorillonite into fine powder with a particle size of 150-3000 mesh.

5. Ball mill: used for fine grinding and mixing of montmorillonite powder.

Separation and classification equipment

1. Vibrating screen: Separates particles according to size, ensuring uniformity.

2. Air Classifier: Classifies powders by particle size to improve the quality of the final product.

Drying equipment

1. Rotary dryer: removes moisture from montmorillonite powder to achieve the required dryness.

2. Fluidized bed dryer: ensures efficient and uniform drying of powders.

Mixing and blending equipment

1. Ribbon mixer: Mix the montmorillonite powder with other ingredients evenly.

2. Paddle Mixer: Provides thorough mixing of powders to ensure consistency.

Conveying equipment

1. Belt conveyor: transports montmorillonite powder between different processing stages.

2. Screw Conveyors: Efficiently transport powders within processing plants.

Packaging Equipment

1. Automatic packaging machine: Pack the processed montmorillonite powder into bags or containers for distribution.

2. Filling Machine: Ensures accurate and efficient filling of powder into packaging units.

These machines work together to process the montmorillonite raw material into a high-quality fine powder suitable for a variety of applications.

-

Previous:What is Bauxite Powder?

Next:What Is Feldspar Powder?